-

By containing only the components necessary to meet each laboratory’s specific needs, Astell autoclaves have a low embodied energy use, and are therefore greener.

By containing only the components necessary to meet each laboratory’s specific needs, Astell autoclaves have a low embodied energy use, and are therefore greener.

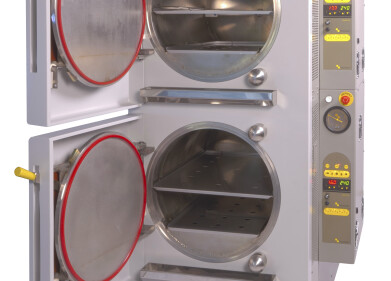

Autoclaves

Greener Solutions for Autoclave Energy Efficiency

Apr 26 2022

With steam sterilisation temperatures and pressures well established, autoclaving within a vessel of a known size requires a predefined quantity of energy. To be energy-efficient during thermal sterilisation, autoclaves must reach - and hold - a sterilisation temperature and pressure without heat loss to the environment, but also drop back to room temperature and pressure effectively during cooling stages.

Astell are innovators in energy efficiency - their autoclaves: capture and reuse heat energy that would otherwise be lost; use the minimum necessary volume of water to generate steam; generate that steam very quickly to minimise the opportunities for heat loss.

Yet these technical developments can only go so far, and Astell’s greatest energy saving happens before the autoclave is ever switched on.

Astell request that their potential customers supply detail of what they plan to sterilise. This allows the autoclave manufacturer, founded in the Victorian era, to produce devices that include only the specific hardware required to meet the user’s needs.

“Constructing autoclaves for the end user’s specific needs allows us to save our customers from large bills,” said Sales & Marketing Director, Paul Birchmore. “It also allows them to help save the planet by keeping the resources that would go into producing unnecessary components in the ground.”

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan