Autoclaves

Different needs, different choices

Nov 13 2024

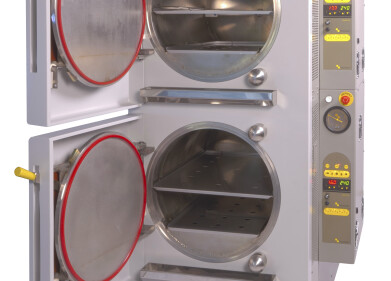

In a busy laboratory environment, often with overlapping workstations, many individuals or teams may need to use an autoclave simultaneously. Whilst loads may need to be segregated and sterilised separately for safety reasons. This could result in a build-up, creating delays and potential safety issues. Having two autoclaves working independently mitigates this possible issue, but takes up valuable lab space. For this reason, Priorclave has developed a unique range of stacked autoclaves, available with dual 150-litre or dual 200-litre capacity cylindrical chambers. These unique autoclaves enable a laboratory manager, who would otherwise require a large 300 or 400-litre chamber autoclave, or two separate autoclaves, to obtain the same capacity in the compact footprint of a single autoclave half the size.

Both Priorclave’s EH150STK and EH200STK stacked autoclaves feature two chambers that can also be used simultaneously or separately at differing times. Each autoclave chamber has its unique sterilisation settings, ensuring the correct temperature is used for the right length of time – with no need to compromise on results! Controlled by two Tactrol®3 process controllers that are exclusive to Priorclave, enabling all possible settings, from simple cycles to fully featured multi-program sterilizing operations with printed records, all achieved at the press of a button. Settings and programming of functions are accessed through a keypad and are displayed on the high-resolution LCD panel, this has significant advantages in a laboratory environment allowing adjustments to be made and processes checked without the need to remove protective gloves. Having two separate chambers controlled by their own dedicated Tactrol®3 control unit ensures each chamber performs safely and efficiently every time.

Priorclave’s EH150STK and EH200STK aren’t just flexible in functionality, they’re versatile for different sectors. From life sciences, pharmaceutical and industrial to agriculture, food production and brewing, from sterilization to accelerated ageing tests – Priorclave’s autoclaves perform, ensuring results you can rely on. Their modular design makes it even easier and quicker to make adjustments or upgrades at a later date, adapting your autoclave to your changing lab requirements. By eliminating corners within the autoclave’s chamber, both models benefit from improved steam circulation, preventing cold pockets and ensuring complete sterilization without excessive cycle times or chronic failed loads.

As with every autoclave designed and built in Priorclave’s UK manufacturing facility, exterior surfaces feature an anti-microbial finish which is highly effective at providing life-long control of harmful bacteria, further reducing the risk of cross-contamination.

Priorclave knows just how important it is to correctly pair the right type of autoclave with your predicted workloads, ensuring that you save time, water, energy and funding. This is why Priorclave provides a personal and tailored solution, through its approved local distributors. To discover just how affordable and impactful a Priorclave autoclave can be, visit the website to find your nearest distributor.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan