-

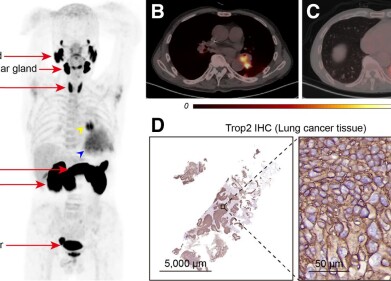

Eliminated hazard without Hydrofluoric acid

Eliminated hazard without Hydrofluoric acid -

Hazard with Hydrofluoric acid

Hazard with Hydrofluoric acid

News & views

No more Hydrofluoric acid, improving lab safety

May 20 2013

Make your Lab safer for all by lab automation and innovative thinking…Here is a very interesting development by Freeport-McMoRan for use with their Automation systems by NUCOMAT, Belgium:

“NO MORE HYDROFLUORIC ACID”

Article from “The Tech Miner” – Freeport-McMoRan – Copper & Gold – 2013

“Employee safety is a top priority at Freeport-McMoRan, whether it’s in the mine or in the Lab. That’s why our Lab employees researched ways to analyse copper from blast hole samples without the traditional use of premixed hydrofluoric acid, or HF, in the process”.

Kale Schaub, Research Engineer, and Jim Williams, Principal Chemist led the team effort to find ways to eliminate the use of HF in the Lab while maintaining the integrity of the Total Copper analysis or TCu. After 18 months of engineering different methods, they came up with a successful solution: create the digestion mixture inside each flask instead of purchasing it premixed. “Rather than having employees handle premixed HF in large quantities, we found a way to create it inside flasks using two inert salts: calcium fluoride and potassium chlorate, which are much safer to handle” Schaub said. “This has significantly improved the safety of our automated NUCOMAT Lab units. For the last few months, all seven NUCOMAT units have been feeding the two salts along with nitric acid separately into each flask.

“This was even more successful than we thought it would be” Williams said. “The chemistry, the mechanics, everything about it is operating better than we thought it would. Instead of handling a toxic substance, our employees now handle salts that do not pose a significant hazard”.

Not only are employees no longer exposed to highly hazardous chemicals, but they have eliminated the use of 55 gallon drums in the Lab. They now transport less hazardous acids in five gallon containers. “Transporting acid in smaller containers is another major improvement in our Lab”, Williams said. “In the case of a spill, cleaning five gallons of weak acid would be much easier than cleaning 55 gallons of a very hazardous solution.

Since the Laboratory opened in 2004, chemists and lab technicians have used a highly corrosive mixture of HF, nitric acid and potassium chlorate to “digest” ore from blast hole samples to perform a TCu. During the digestion, all elements in the ore, including copper, silica and iron, are dissolved in the acidic solution. Chemists then can quantify the total amount of copper in each sample and use that number to project recovery rates for ore from each blast hole.

HF and nitric acid are integral parts of the process because they can completely break down ore samples in minutes.

“Nitric and hydrofluoric acids were mixed with potassium chlorate salts, stored and transported in 55 gal drums before being used in the Lab” Schaub said “The problem with that was the solution would react and create hazardous off gasses everywhere it was used”.

Inhaling off-gasses or touching the solution had the potential of causing serious health issues. The HF-nitric acid mixture also had the potential of ruining equipment. “Every once in a while, we would get leaks,” Schaub said. “Anything the solution touched was essentially destroyed”. Using the new process, that’s less likely to happen because when mixed together, the nitric acid reacts with the calcium fluoride and creates HF. That combined with the other components of the mixture produce the same potent mixture as the premixed HF. “Management was extremely supportive of this project” Schaub said “they gave us the green light we needed to make this process safer for our employees”.

For more information on how the NUCOMAT automation systems can make your Lab safer and more efficient, please either contact us at DSL, or NUCOMAT

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan