Liquid handling

Precise solutions for low flow liquid measurement

Mar 16 2024

Low-flow measurement is increasingly prevalent across various industries. Yet, as flow rates decrease, the task of controlling and measuring them becomes progressively more challenging. This poses a significant obstacle for users and flow sensor manufacturers alike in their search for cost-effective and reliable flow measuring technologies.

While there isn't a standardized definition for ‘low flow’ concerning fluidics handling, these applications face distinct challenges compared to larger flows. The minimal volume of liquid involved makes low-flow systems highly sensitive, amplifying concerns about flow stability and performance. Even minor disruptions in process or environmental conditions can significantly affect flow stability in low-flow scenarios.

In the markets where Titan Enterprises operates, low flow rates are considered to be those below 50 ml/min, with many customers seeking flow rates ranging from 2 to 20 ml/min.

Neil Hannay, Senior R&D Engineer at Titan Enterprises, noted: "We are observing a significant rise in the demand for low flow measurement technologies, fuelled by various industries shifting towards transporting highly concentrated liquids that are later diluted at the point of use. This transition results in substantial savings on transportation and storage expenses, while also yielding positive environmental benefits."

From cleaning fluid additives to beer or soda syrups and flavourings, chemical additives for oil and fuel, paint pigments, or drug administration, the use of low-flow flowmeters is essential. They ensure precise dosing of these concentrated fluids at the end of the process, facilitating accurate dispensing for the correct dilution.

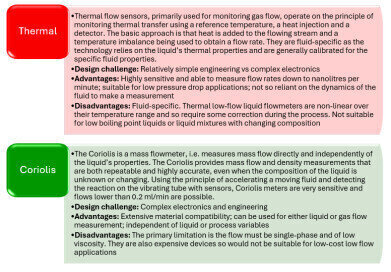

As mentioned, measuring low flow presents a challenging application to address. The energy available in low liquid flow is often inadequate to drive most mechanical flowmeters to provide linear results. Electronic flow meters, on the other hand, may face limitations such as sensitivity, zero drift, and slow response times. This analysis covers five types of flow meter - Ultrasonic, Turbine, Oval Gear, Thermal, and Coriolis - and assesses their suitability for low flow measurement.

Selecting the most appropriate high-precision flow sensor for your application is crucial, as flowmeters can often be the most constraining element of a low flow fluidic system.

Neil stated: "We recognise a robust market demand for low flow meters, and we are presently collaborating with two international OEMs to devise a solution for measuring ultra-low flows leveraging our oval gear technology and miniaturised gears."

More information online

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan