-

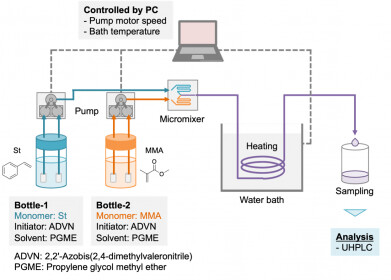

The flow synthesis reactor with two bottles containing a monomer, initiator and solvent mixed using a micromixer. The synthesis is controlled with AI-based design of experimental conditions such as the temperature and a flow rate. Credit: Nara Institute of Science and Technology

The flow synthesis reactor with two bottles containing a monomer, initiator and solvent mixed using a micromixer. The synthesis is controlled with AI-based design of experimental conditions such as the temperature and a flow rate. Credit: Nara Institute of Science and Technology

Research News

Machine learning enhances polymer production efficiency

Dec 03 2024

Machine learning is helping optimise polymer manufacturing by reducing the reliance on expensive and time-consuming experimentation. Polymers, such as plastics, are essential in a wide range of applications, from packaging and automotive to medical devices and optic fibres. Their properties are determined by their monomers - the chemical building blocks that form a polymer. However, controlling the chemical behaviour of monomers during production is a complex challenge.

A team led by Professor Mikiya Fujii at Japan's Nara Institute of Science and Technology has demonstrated the potential of machine learning to optimise this process. Using mathematical modelling, the researchers were able to streamline the polymerisation process and identify optimal manufacturing conditions. Their findings were published in Science and Technology of Advanced Materials: Methods.

To train the machine learning model, the team developed a polymerisation process that quickly generated experimental data. They focused on producing a styrene-methyl methacrylate co-polymer, synthesised by mixing the monomers in a solvent with an initiator and heating the mixture in a water bath.

The researchers employed flow synthesis, a technique that mixes and heats solutions in a continuous flow. This method offers better mixing, efficient heating, and precise control of variables like heating time and flow rate, making it ideal for data collection.

The machine learning model analysed five critical variables: initiator concentration, solvent-to-monomer ratio, styrene proportion, reaction temperature, and time in the water bath. The goal was to achieve a final product with 50% styrene content.

Surprisingly, the model required only five calculation cycles to determine optimal conditions, which included a lower reaction temperature, extended time in the water bath, and reduced monomer concentration in the solvent. The researchers were particularly intrigued by the impact of solvent concentration, which proved as significant as monomer proportions.

“Our results demonstrate that machine learning not only can explicitly reveal what humans may have implicitly taken for granted but can also provide new insights that weren’t recognized before,” Professor Mikiya Fujii said. “The use of machine learning in chemistry could open the door for smarter, greener manufacturing processes with reduced waste and energy consumption.”

More information online

The research was published in Science and Technology of Advanced Materials (STAM)

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan