-

High-Pressure Heatless Dryers, HP-HPSA are part of Hi-line’s bespoke range.

High-Pressure Heatless Dryers, HP-HPSA are part of Hi-line’s bespoke range. -

The HPSA-CT (Carbon Tower) is a three-stage dryer with the Carbon Tower added after the adsorption dryer.

The HPSA-CT (Carbon Tower) is a three-stage dryer with the Carbon Tower added after the adsorption dryer. -

Two new models to the HPSA range, HPSA 70 and HPSA 100 bring the total number of standard models to 12, with flow capacity from 75 to 1130 scfm.

Two new models to the HPSA range, HPSA 70 and HPSA 100 bring the total number of standard models to 12, with flow capacity from 75 to 1130 scfm. -

The Hi-line HPSA (Heatless Pressure Swing Adsorption) series of desiccant dryers features proven technology developed and manufactured in the UK.

The Hi-line HPSA (Heatless Pressure Swing Adsorption) series of desiccant dryers features proven technology developed and manufactured in the UK.

Laboratory products

Class-leading Desiccant Air Dryers: Expanded range fulfils all application needs

Feb 18 2022

Hi-line Industries, an established and reputable UK manufacturer of high-quality compressed air purification equipment, can offer a fully featured range of desiccant air dryers. The company’s series of class-leading HPSA heatless dryers includes new standard models, the recently launched HPSA-CT (Carbon Tower) version, plus the bespoke HP-HPSA (High Pressure) model. As a result, Hi-line can fulfil the needs of any company that needs dry, clean compressed air or nitrogen, whatever the application.

The Hi-line HPSA (Heatless Pressure Swing Adsorption) series of desiccant dryers features proven technology developed and manufactured in the UK by the company’s expert engineering team working to approved engineering standards. These ‘plug and play’ units with digital control panels come skid-mounted with their own filtration package (pre- and after-filtration). Available for next-day delivery, all standard HPSA dryers use Dri-Zorb 27 desiccant media that delivers constant low dewpoints while consuming the lowest possible quantity of regeneration air.

In order to meet ongoing industry demand, Hi-line is constantly looking to expand its portfolio, recently enhancing the HPSA range with two smaller capacity models. The new HPSA 70 and HPSA 100 bring the total number of standard models to 12, with flow capacity from 75 to 1130 scfm (larger heatless dryers are available if required).

Another recent introduction to the range is the HPSA-CT (Carbon Tower), a three-stage dryer with

the Carbon Tower added after the adsorption dryer. Clean, dry air passes through the Carbon Tower and adsorbs gases and aerosols dependant on requirements and the zeolites selected. This capability makes the HPSA-CT extremely flexible and suitable for use in many specific applications. The Hi-line HPSA-CT features pre-filtration sub-micron oil removal and safety valves as standard, as well as an after-filter for particulate removal. A total of 12 standard HPSA-CT models are available with flow capacity from 80 to 1130 scfm. Larger HPSA-CT dryers are available upon request.

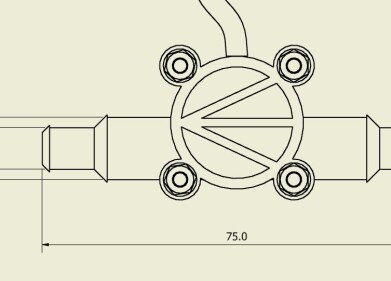

Hi-line can also now offer its bespoke HP-HPSA (High Pressure) heatless dryer. This model features the same proven HPSA technology, just running at high pressure. Control air is at 7 bar, but with elevated pressures up to 450 bar for specific applications such as P.E.T. blowing and moulding, R&D applications, breathing air/diving applications, speciality gas blending and laser cutting.

Every HPSA model in the extensive Hi-line range is a fully automatic, IP65-rated, self-contained unit featuring HDC1 digital dewpoint controller, stainless steel pipework, independent switching valves, exhaust silencers and a one-year warranty on parts and labour. Options include the company’s AEMS - Automatic Energy Management System (with digital dewpoint readout, high-humidity alarm, and set and demand regeneration), dewpoint to -70°C, and automatic start/stop control.

More information online

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan

.jpg)