-

-

.jpg)

-

Understanding Pressure Swing Adsorption and Membrane Technology used to Generate Nitrogen

Understanding Pressure Swing Adsorption and Membrane Technology used to Generate Nitrogen

Laboratory products

How to optimize the Nitrogen supply to LC-MS/MS systems?

Jun 04 2024

The quality of nitrogen used in LC-MS directly impacts the performance and sensitivity of the instrument, influencing the detection limits, signal-to-noise ratios, and overall data quality. Therefore, the use of high purity nitrogen is imperative to maintain the integrity of the analytical process, minimize background interference and optimize sensitivity and reproducibility in LC-MS analyses.

For high purity nitrogen supply to LC-MS/MS instruments, look no further than the CALYPSO SERIES by F-DGSi, a series of nitrogen generators offering a choice between Pressure Swing Adsorption (PSA) and Membrane technologies to meet diverse purity and application requirements.

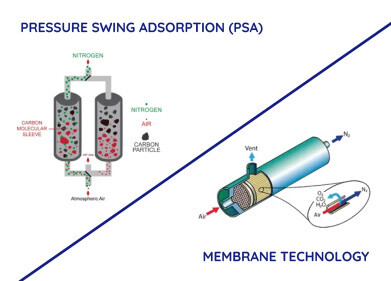

Understanding pressure swing adsorption

Nitrogen generators with PSA technology are designed to absorb ambient air through an integrated air compressor. The pressurized air is first pre-filtered to eliminate water and dust present in the atmospheric air. This pre-filtered air stream is then passed through a CMS bed, also called carbon molecular sieve, which is in purification mode.

Pressurized air is passed through the CMS column so that O2, CO2 and H2O molecules and hydrocarbons are retained in the molecular sieve. The nitrogen leaving the CMS column can be stored in a tank.

During this CMS filtration phase, the second column is regenerated by depressurization supported by a nitrogen countercurrent. The process is cyclic and fully automatic, ensuring a continuous production of clean, dry and high purity nitrogen, offering purities of over 99.999% with a lifespan of 10+ years.

Understanding membrane technology

Nitrogen from the air is absorbed inside the generator. This air flow is compressed and pre-filtered to pass through a membrane made of semi-permeable polymeric hollow fibers allowing a molecular separation.

Small molecules such as O2 and CO2 diffuse through the pores of the membrane while the larger nitrogen remains in the membrane flow. Nitrogen gas is then left in place and is ready to be delivered to the instrument. This simple system produces nitrogen with purities of less than 99.5% with a lifespan of < 5 years.

Why would you opt for CALYPSO?

Beyond the convenience of on-demand production, opting for a CALYPSO nitrogen generator offers numerous benefits:

- Constant supply of nitrogen with permanent purity from the ambient atmosphere;

- Extensive range of models offering purities from 99.5 % to 99.999%;

- High safety as a very little amount of nitrogen is stored internally and only low pressure is used;

- High convenience as no time is wasted on ordering, receiving, storing and changing cylinders!

- Cost savings up to 50% by replacing the cylinder technology with a constant nitrogen production;

- Sustainability as generators are a more environmentally friendly and sustainable source of gas supply;

- Effortless management of your parameters through an intelligent touch screen and remote connection;

- Quiet operation with the soundproofed compressor box.

With over 15 years of manufacturing expertise, CALYPSO generators are endorsed by leading instrument manufacturers, guaranteeing an optimal gas quality. Discover more gas generators (Hydrogen, Air Zero, Nitrogen) and Liquid Nitrogen generators to optimize gas supply and contact us for more information.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan