Fume extractors

Reducing Fan Energy Consumption in Fume Extraction Systems | EC Technology

Sep 15 2021

The already impressive range of corrosive fume fans from Axair Fans has now been extended to include an energy efficient range featuring B34 type IE5 EC motors located outside of the airstream. As the market demands more energy efficient systems, the introduction of the EC range of fans allows fume cupboard manufacturers to reduce their fan energy consumption by up to 20% without affecting performance, ultimately enhancing the energy efficiency of the entire fume extraction system. System designers are now keen to look at all options to reduce energy consumption with laboratories and considering reducing the amount of energy used by the extraction fan itself is a good starting point.

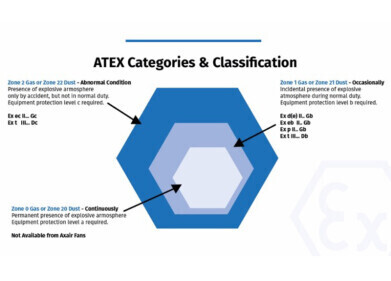

Complementing the existing range of chemical fans, including the ATEX plastic extract range, from Axair, the IP55 polypropylene collection of EC fans and motors are available in variety of sizes in both single and three phase variants covering airflows from 20-9000m3/hr and pressures to 1500Pa.

Single phase EC motors come equipped with integrated drive and IP55 protection against dust and ingress. An outdoor weatherproof cowl can be supplied for additional ingress protection if required.

Three phase EC IP55 motors are supplied with a supporting IP66 inverter drive for accurate speed control of the fan motor to match the exact ventilation needs of the application. Controlling the speed of the motor further allows for energy saving by limiting the amount of energy needed to power it. As an example, slowing a fan motor by 20% saves nearly 50% in energy consumption.

The introduction of an energy efficient range of corrosion resistant fans is of huge benefit to end users making a conscious effort to reduce their building energy consumption. Laboratories are one of the largest energy consuming sectors in the UK, consuming between four to six times more energy per square metre than standard offices or commercial buildings, predominantly due to the energy intensive ventilation systems necessary to ensure correct airflow and temperature. Energy efficiency in laboratory settings can make an enormous difference when it comes to reducing costs and carbon footprints. The integration of EC Fans within fume cupboards is a significantly simple step towards making this change.

With over 25 years of experience, Axair supports a large network of UK fume cupboard manufacturers and those within the environmental corrosive fume market with their range of industrial fans. Corrosion resistant fans are supplied on either metal or outdoor polypropylene pedestals and are specified to match the exact requirements of the applications operating and performance duty.

Axair welcome enquiries from new and existing customers or end users for EC, low pressure, high pressure or ATEX single or three phase fans in any market or application.

To view datasheets and more product information contact us or to start a live chat with one of our fume fans experts visit our website to discuss your requirements.

Digital Edition

ILM 50.2 March 2025

March 2025

Chromatography Articles - Effects of small deviations in flow rate on GPC/SEC results Mass Spectrometry & Spectroscopy Articles - Waiting for the present to catch up to the future: A bette...

View all digital editions

Events

Mar 18 2025 Beijing, China

Mar 20 2025 Brussels, Belgium

Mar 20 2025 Chandigarh, India

ACS National Meeting & Expo, Spring 2025

Mar 23 2025 San Diego, CA, USA

Mar 25 2025 Paris, France