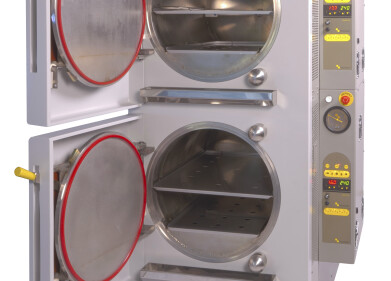

Autoclaves

WHO Compliant Autoclaves for Safer Coronavirus Research

Apr 07 2020

According to the World Health Organization (WHO) guideline ‘Laboratory biosafety guidance related to the novel coronavirus (2019-nCoV)’ from 12 February 2020, biosafety levels BSL-2 and BSL-3 are required in order to safely handle COVID-19. Laboratories at which diagnostic work such as virus sequencing is conducted should conform to the BSL-2 standard, while laboratories at which the virus is cultivated or otherwise present in high concentrations should operate on the basis of BSL-3. Systec autoclaves are perfectly suited to comply with the safety guidelines at appropriate laboratories that have been published for this purpose by the WHO.

Systec laboratory autoclaves are ideal for sterilisation of contaminated waste, instruments, culture media or laboratory equipment to prevent the accidental spread of the coronavirus. This is primarily thanks to three key properties that the WHO stipulates as mandatory or recommends for BSL-2 and BSL-3-compliant sterilisation equipment.

Systec autoclaves have a vacuum system that removes the air from the sterilisation chamber of the device in several vacuum pulses before the actual autoclaving process. The cold air can thus be removed from solids and porous materials to guarantee the sterilising effect of the saturated steam subsequently injected. Thus, for example, Systec autoclaves keep coronavirus pathogens in cold-air enclosures from surviving the heating process.

A possible danger with autoclaving is the potential of certain pathogens to escape through the exhaust air during the sterilisation process before the temperatures required for inactivation have been reached. When working in connection with the coronavirus, you can easily prevent this effect by using Systec autoclaves in combination with the feature of exhaust air filtration. Exhaust air filtration uses sterile air filters with a heat-resistant PTFE membrane, which reliably retains microorganisms with a pore size of 0.2 μm. As a result, all escaping gases are passed through the above-mentioned sterile air filter in the heating and sterilisation phase. This and the additional condensate activation ensure that no non-sterile or contaminated material can escape from the sterilisation chamber.

Systec steam sterilisers digitally document all sterilisation processes. Among other things, the system records the sterilisation temperatures and periods so that any application errors can be traced by laboratory employees. If there is a coronavirus contamination due to faulty work processes, it can be determined exactly which sterilisation items are affected and when the faulty process occurred, allowing a resulting infection chain to be quickly identified and interrupted.

China, as the epicentre of the epidemic, relies on Systec solutions to research and contain the coronavirus. The Chinese Center for Disease Control and Prevention (CDC) has already purchased a large number of autoclaves through its subsidiary in Shanghai for use at BSL-2 and BSL-3 laboratories across the country and also in Taiwan.

Currently, Systec autoclaves are used in many other countries for the coronavirus research.

More information online

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan