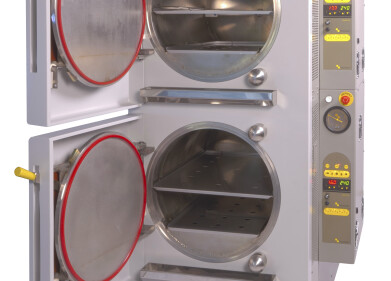

Autoclaves

The Alternative Lab Autoclave

Nov 05 2014

Launch of the Priorclave Q63, 320 litre front loading capacity autoclave has given laboratories a real opportunity to consider this more economically priced cylindrical chamber design rather than investing in a large rectangular chamber steam steriliser. Users of the Q63 autoclave may also benefit from lower overall running costs associated with reduced power and water usage.

Since chamber size has a major influence on autoclave selection, Priorclave designed the cylindrical chamber of the Q63 with a taller profile than that found in most ‘cylindrical’ machines, giving these autoclaves an impressive load capacity ideally suited to sterilising larger bulky items as well as enabling small and taller items could be sterilised in a single process. This has proven to give lab equipment purchaser an extremely viable alternative to large rectangular chamber autoclaves where model selection is based on items size alone.

The Q63 320l Priorclave is part of an extensive autoclave range manufactured in the UK and follows one of the most stringent design and build programs, conforming to either PED or ASME standards depending on which country the autoclave will be installed. Obviously a key component and central to the overall robustness of the autoclave is the make-up of the actual chamber.

At Priorclave’s manufacturing centre in SE London all cylindrical chambers are constructed in 316 stainless steel using a bespoke seam welding system. This seam welder was designed by the company to create one of the strongest and straightest seams to be found in any round chamber autoclave. This is just part of the attention to detail given to each autoclave built, ensuring overall strength, reliability and exceptional performance of every Priorclave leaving this dedicated manufacturing centre.

The 320 litre Q63 front loading autoclave has a 630mm chamber which is 1025mm deep and for easy, convenient loading Priorclave has given the Q63 – 320 litres autoclave a loading height of just 725mm. Whilst offering increased loading, the combination of features such as forced air cooling to reduce cycle times and automatic timed free-steaming for improved air removal add to the overall sterilising performance of the Q63 autoclave.

All operating settings are programmed easily through the Tactrol® 2 microprocessor controller which is standard across the entire Priorclave range. This can be configured to log all temperature, pressure time and cycle data into a single compact archive file which can be subsequently downloaded onto a USB flash drive for transfer to computer. This enables operational data to be forwarded from anywhere in the world direct to Priorclave’s UK Service Centre for technical assistance in fine-tuning and clarification of autoclave performance if required.

Priorclave, a household name within the global laboratory autoclave market, has developed and manufactures an impressive range of top and front loading steam sterilisers that include benchtop as well as front loading rectangular, power door and double-ended designs, laboratory autoclaves that have become synonymous with quality, reliability and highly efficient autoclaving processes.

The build quality of the Q63 – 320L front loading autoclave incorporated epoxy coated panels and frame members which are treated with an anti-bacterial agent highly effective against all bacteria and fungi including MRSA, preventing cross contamination within the laboratory.

Digital Edition

LMUK 49.7 Nov 2024

November 2024

News - Research & Events News - News & Views Articles - They’re burning the labs... Spotlight Features - Incubators, Freezers & Cooling Equipment - Pumps, Valves & Liquid Hand...

View all digital editions

Events

Nov 20 2024 Karachi, Pakistan

Nov 27 2024 Istanbul, Turkey

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA