Lab Safety

Suncombe helps to deliver complex effluent treatment plant at Pirbright Institute

Oct 24 2024

Suncombe, a leading global supplier of hygienic process equipment and systems, played a leading role in the initial design, construction, implementation and commissioning of a new Effluent Treatment Plant (ETP) for the ISO11 building at The Pirbright Institute in Surrey, UK. Pirbright is a world leading centre of excellence in research and surveillance of virus diseases of farm animals and viruses that spread from animals to humans.

The ISO11 building is used to conduct research into areas such as vaccine development, efficacy testing and viral transmission biology. The site houses animal units and conducts tests on pathogens at containment level four and since this is the highest containment level possible this project had a particular focus on highly secure solutions. The project was initiated to replace the existing ETP, which was very old and with outdated controls, with a brand new, state-of-the-art, treatment system.

External structure

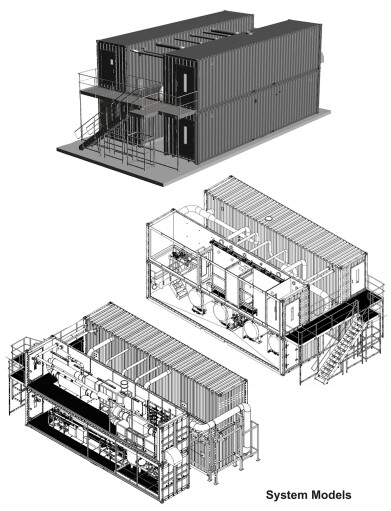

Due to the lack of available space in the ISO11 building, it was decided to design an externally-sited structure, made of specially manufactured shipping containers. To avoid a long period of downtime the client needed to keep the building running with the old ETP, and then programme a much shorter change over. That was very much facilitated by building an external ETP.

These ETP containers were manufactured to provide a 100% contained environment as the operations involved ‘high consequence’ pathogens up to and including SAPO4 (including Foot and Mouth Disease Virus) and ACDP Hazard Group 3 (viruses that can cause serious disease in humans).

Having a containerised external system brought its challenges, because of the need to provide pipework groups through the containment boundary of the building which had to be protected by a significant steel structure.

One of the benefits of building a containerised ETP was that it allowed the equipment to be designed, manufactured, connected, installed and tested off-site and enabled the inclusion of all of the utilities and control systems in this single module.

Performance testing

The team at Suncombe identified and specified all the performance testing which they needed to carry out in order to provide test results as well as demonstrations. Also it developed the plan for testing and commissioning of the final system early in the project programme.

The Suncombe BioSuite Control Systems have been specifically developed for ultimate control of these highly critical decontamination systems. They include a use-friendly interface allowing visualisation, reporting and audit of the process. Also it incorporates system redundancy, to ensure continued operation and safe shutdown availability, together with functional safety logic and elements.

The Pirbright engineering team attended off-site acceptance testing of the process system at Suncombe. The plant was then installed on-site, and all the testing was then repeated in situ. After successful site acceptance testing there was a further period of ‘confidence testing’ with Pirbright, using ‘live’ animal effluent.

Steve Overton, Suncombe Operations Director commented: “I am grateful to Pirbright and project management company 3PM personnel, as well as the Suncombe team, for delivering this challenging project.”

More information online

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan