Autoclaves

Lab Autoclave Perfect for Taller Loads

Mar 11 2019

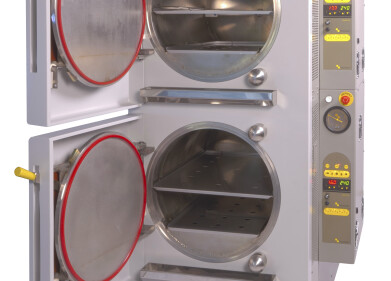

For laboratories looking to sterilise tall items such as fermentors and large capacity Erlenmeyer flasks, or have a high-density load requirement but have limited floor space, the latest version of the Priorclave C60 top loading autoclave could prove to be the perfect choice.

Designed and built by one of the UK’s leading autoclave manufacturers, the Priorclave compact C60 laboratory autoclave is a versatile compact top-loading 60 litre laboratory autoclave with a 60 litre chamber, features advanced sterilising cycles yet requires just 472 x 620mm of floor space. It’s the ideal general lab or research autoclaves for laboratories looking to process tall items, have a high-density load requirement; typical this machine accommodate easily ten one-litre or sixteen 500ml bottles, alternatively six one-litre Erlenmeyer flasks.

This model incorporates the electrical heating elements within the actual chamber, this provides for faster and more efficient build-up of high-temperature, pressurised sterilising steam for more effective sterilising throughput. It makes the C60 top-loading autoclave ideal for either continuous or periodic sterilising requirements, a very cost-efficient autoclave achieving lower operations costs. The latest datasheet shows the overall capabilities of this compact top-loading autoclave

With total control over production, Priorclave is able to add to a basic model, introducing components from an extensive list of options and accessories. This ensures the tailored autoclave will be the ideal match for your sterilising requirements and supplied as standard or with vacuum facility.

Access to the sterilising chamber is via the patented Quickseal single-action door closure/opening mechanism. Suited to one handed operation, the mechanism incorporates thermal and pressure locks preventing opening at unsafe temperatures and pressure to prevent personal injury.

Programming of the sterilising set-up of time and temperature as well as selection of special features such as freeâ€steaming and media warming is through the new Tactrol®3 microprocessor control system. Features such as free steaming can improve air removal in difficult loads and/or reduce temperature lag between the load and the autoclave, reducing process time at higher temperatures. It also incorporates a media warming feature that cycles the temperature between approximately 45o to 55oC once the factory preâ€set temperature of 45oC has been reached. This continuous until the door is opened, allowing nutrient media, for example, to be held as a liquid until it is needed, especially when used along with the delayed start function.

The compact, C60 top-loading autoclaves is now also available with an 85 litre tall sterilising chamber for customers requiring increased depth.

When buying into the Priorclave brand you gain an autoclave in the knowledge that every care has been taken to build robust machines, reliable sterilising performance, with a superior exterior finish to body panels and frames that eliminate possible cross-contamination within laboratories.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan