Autoclaves

Creating a Sterile Path to prevent Cross Contamination

Jan 14 2019

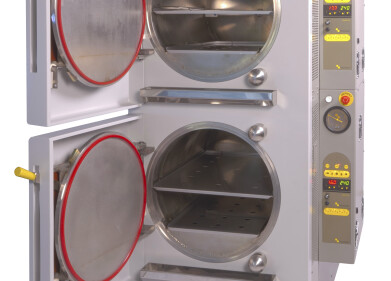

With a Priorclave pass-through (double-door) laboratory autoclave it is possible to maintain the integrity of laboratories and protect the surround environment by creating a sterile path for media and waste as it passes in and out of a sealed laboratory.

Double-door autoclaves can be considered a bespoke design, albeit one that is created by adding a second door to a standard model. This is where the UK design and laboratory autoclave manufacturing centre of Priorclave is a success as it adapts a standard steam steriliser or develops a totally unique autoclave to meet customer requirements. These robust designs have an uncompromising level of safety that includes interlocks preventing the simultaneous opening of doors at either end of the chamber.

The QCS 150 Pass-Through autoclave is the latest and smallest double-door laboratory autoclave to be introduced by Priorclave, it has a 150 litre front loading stainless steel chamber and is configured to accommodate up to 20% more load capacity than other steam sterilisers of the same specified size. This provides greater versatility where the scale of items to be sterilised may vary significantly, allowing both small and taller items abled to be processed in a single pass.

Priorclave is also able to offer double-door autoclaves based around a number of its many standard models with chamber capacities up to 700 litres.

Each QCS 150 double-door laboratory autoclave is partly bespoke, Priorclave configuring the functionality of its on-board Tactrol® controller to suit lab requirements. A typical set-up could be that only one side of the double door steriliser has access to the full control system, the other side of the autoclave equipped with just a screen to show process status so that lab staff are continually aware when a job is complete and it is safe to remove the media or waste. Where there is concern about bio-hazardous material in the autoclave a microbiological filter can be fitted. Unfiltered condensate is returned to the autoclave for sterilisation.

The Tactrol® microprocessor provides easy yet variable settings of process time and temperature, all supported by graphic indication of cycle status. Just set the temperature and time required, select any options needed and press start, operation is fully automatic once the cycle has started. The tough, clear control panel displays continuously process status.

Since each installation site is different, it may require doors to be hinged on the left or right as well as consideration to location of electrical, water and drain services. This is where the in-depth knowledge of the Priorclave sales and service team is a value asset, they are always on hand to advise on critical installation issues, ensuring the autoclave build program accommodates local site requirements for a smooth path from delivery to installation and operation.

The overall design and build of the QCS 150 Pass-Through laboratory autoclaves take place at Priorclave’s UK manufacturing centre where it introduces a bulkhead mount at the correct position to facilitate a strong structural fix into a dividing wall between the sterile lab and non-sterile areas. Once installed the double-door Pass-Through Priorclave is the perfect partner working as an interface between sterile and non-sterile areas.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan