Pumps / Valves

Generate Low Vacuum Pressure for Electron Microscopy with Diaphragm Pumps

Jul 13 2021

Various analytical methods like mass spectrometry, electron microscopy or x-ray applications are used to provide information about the objects to be investigated. Therefore, often individual and customised vacuum solutions are needed to develop the best vacuum performance. To get a high resolution and magnification in the electron microscopy you need a high vacuum. It is particularly important to avoid vibrations of the vacuum system.

Electron microscopy can be used in many sectors

Scanning electron microscopy (SEM) is an analytical method used in a wide range of applications. Scientists use it to learn more about microscopic organisms or crystalline structures. SEM is also used in industrial processes to examine the surface compositions of components and products. Applications range from the semiconductor industry, food monitoring, medical devices and microelectronics to general production monitoring.

Why vacuum is necessary for SEM

In this type of electron microscope, the electron beam scans the sample in a raster pattern. The entire electron column must be under vacuum. Like all the components of an electron microscope, the electron source is sealed inside a special chamber in order to preserve vacuum and protect it against contamination, vibrations or noise. In the absence of vacuum, other atoms and molecules can be present in the column. Their interaction with electrons causes the electron beam to deflect and reduces the image quality. Furthermore, high vacuum increases the collection efficiency of electrons by the detectors that are in the column.

Successful with the right equipment

In this case application with low vibration rates are suitable. The main part of such vacuum systems is the turbopump. In order to achieve the desired pressure range, you also need a backing pump. Various dry backing pumps are available, such as diaphragm pumps, multi-stage Roots pumps or our new scroll pumps.

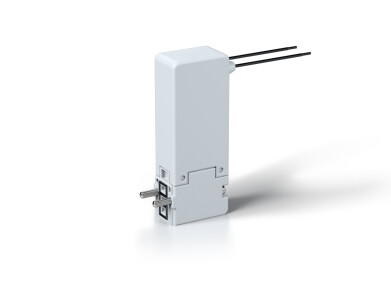

Diaphragm pumps are an optimal solution to generate the required fore-vacuum; as they are very robust and, thanks to their compact design they can be integrated into small analytical systems, mass spectrometers or turbo pumping stations. With the MVP 030-3 C DC, Pfeiffer Vacuum has now introduced a new corrosive gas version of the diaphragm pump. This version features a gas ballast valve and excellent chemical and condensate compatibility. The special choice of materials ensures significantly increased robustness in a wide range of processes. The diaphragm pumps not only do their job reliably, but also quietly and with low vibration. The noise level is below 45 dB(A). The three-stage MVP 030-3 C DC is equipped with a manual gas ballast valve. The accumulation of condensate in the diaphragm pump can be prevented by opening the gas ballast valve. This ensures greater process reliability and a longer service life.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan