-

Figure 1. The High Energy Ball Mill Emax features two grinding stations and a maximum speed of 2000 min-1

Figure 1. The High Energy Ball Mill Emax features two grinding stations and a maximum speed of 2000 min-1 -

Figure 2. Grinding of chitin in the Emax for 8 h at 1300 rpm (left) and in a conventional ball mill for 8 h at 650 rpm (right) with obvious discolouration of the sample. The final fineness achieved in the Emax is 114 µm compared to 158 µm in the ball mill.

Figure 2. Grinding of chitin in the Emax for 8 h at 1300 rpm (left) and in a conventional ball mill for 8 h at 650 rpm (right) with obvious discolouration of the sample. The final fineness achieved in the Emax is 114 µm compared to 158 µm in the ball mill. -

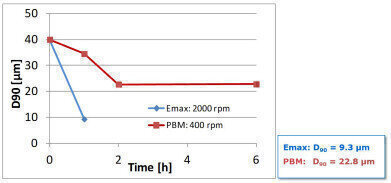

Figure 3. Grinding a graphite sample in the Emax and in a planetary ball mill. The Emax achieves a final fineness below 10 microns which is not possible with the other mill.

Figure 3. Grinding a graphite sample in the Emax and in a planetary ball mill. The Emax achieves a final fineness below 10 microns which is not possible with the other mill. -

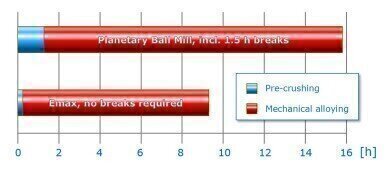

Figure 4. Comparison of a mechanical alloying process of silicon and germanium in the Emax and in a planetary ball mill. The time saving by using the Emax amounts to almost 50%. A better transformation rate and less caking of the sample are further advantages of the Emax.

Figure 4. Comparison of a mechanical alloying process of silicon and germanium in the Emax and in a planetary ball mill. The time saving by using the Emax amounts to almost 50%. A better transformation rate and less caking of the sample are further advantages of the Emax. -

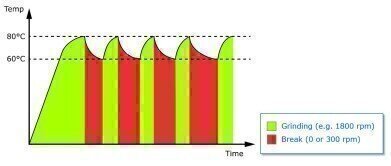

Figure 5. Grinding of polysaccharide in the Emax using the temperature control mode. This function allows grinding within predefined temperature limits with automatic adaptation of grinding breaks.

Figure 5. Grinding of polysaccharide in the Emax using the temperature control mode. This function allows grinding within predefined temperature limits with automatic adaptation of grinding breaks.

Mills and Grinders

The Revolution in Ultrafine Grinding: Emax – Faster, Finer, Cooler

Mar 15 2016

The High Energy Ball Mill Emax is an entirely new type of ball mill with an impressive speed of 2,000 min-1 and a unique grinding mechanism resulting in ultrafine particle sizes after very short grinding times. Thanks to the new liquid cooling system, excess thermal energy is quickly discharged preventing both sample and mill from overheating, even during longer grinding periods. The application examples in this article show impressively that the Emax achieves the desired grind sizes in a fraction of the time that conventional ball mills need without altering the sample properties.

Cooling and Temperature Control

The very high energy produced by ball milling leads to an extreme heat increase inside the grinding jars, therefore cooling can be an essential advantage, especially if heat-sensitive samples are processed. Retsch solved this problem by creating an innovative integrated water-cooling system for the High Energy Ball Mill Emax which ensures grinding without excessive heat build-up. To further reduce the temperature, the mill can be connected to a chiller or the tap. Grinding breaks for cooling, which are unavoidable in conventional ball mills even while grinding at moderate speed, are usually not necessary when using the Emax. Furthermore, the Emax allows the user to carry out the grinding process within a defined temperature range by setting a minimum and a maximum temperature. When the maximum temperature is exceeded, the mill automatically stops and starts again upon reaching the minimum temperature. With conventional ball mills the user needs to find out about the required cycles of grinding and cooling by empirical trials. If the cooling breaks are not long enough, the sample will be warmed too much. The Emax, however, can be operated with variable grinding times and grinding breaks thanks to the definition of the temperature limits. Thus, the grinding process is always reproducible.

High Energy Input

The high energy input of the Emax not only improves grind sizes in the submicron range but is also beneficial for processes to produce new materials, such as mechanical alloying. If the substances have to be pulverised first, they can be pre-crushed directly in the Emax. Usually, the process times for mechanical alloying are several hours; in conventional ball mills additional time for grinding breaks must be added. Producing new material in the Emax not only saves time, there are even more advantages like better transformation rates and less caking of the sample material.

Maximum Safety

The Emax was designed for maximum operational safety. The lids of the grinding jars have to be screwed on the grinding jars, so that these are tightly closed for wet grinding and if pressure increases inside the grinding jars. Sensors control the position of the grinding jar; the mill cannot be started if the position is not correct. Possible imbalances are controlled at all times. If they become too strong the mill automatically stops. The remaining grinding time is displayed and the process can be re-started once balance has been restored.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan