-

Sensmet's µDOES.

Sensmet's µDOES. -

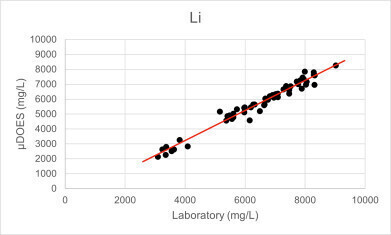

Lithium trial results.

Lithium trial results. -

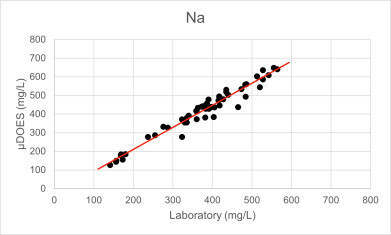

Sodium trial results.

Sodium trial results.

Mass Spectrometry & Spectroscopy

Revolutionising real-time metals monitoring operations

Dec 20 2023

Metso, a global leader in minerals processing and metals refining, recently conducted a field trial in collaboration with Sensmet, evaluating the application of Sensmet's continuous metals monitoring technology at its Pori, Finland facilities. The trial focused on comparing Lithium and Sodium measurements using laboratory ICP-OES analysis with Sensmet's µDOES® continuous analyser. Impressively, the trial showcased a strong correlation between the two methods, particularly under challenging real-world conditions.

Traditionally, hydrometallurgical production processes relied on periodic sampling and laboratory analysis for process control. However, Sensmet's µDOES® analyser, tested under actual field conditions, presents an opportunity to revolutionise lithium production processes by enabling real-time control. This technology addresses the limitations of costly and time-consuming lab analyses.

During the trial, samples were drawn from a process producing battery-grade lithium hydroxide monohydrate from spodumene concentrate. The µDOES® analyser demonstrated its analytical ability in continuously optimising pressure leaching and conversion leaching, delivering results that exhibited excellent correlation with laboratory ICP-OES measurements.

Metso's Veli-Matti Järvinen, Vice President of the Automation Product Group, expressed satisfaction with the trial outcomes, emphasising the significant value anticipated from integrating µDOES® technology into Metso's Courier® HX system for battery metal production and recycling processes.

Metso's extensive evaluation confirmed the outstanding performance of µDOES®, prompting plans to incorporate this technology into selected Courier® HX systems for lithium and sodium analysis. These advanced systems are set to be globally available in 2024, showcasing the transformative potential of µDOES® in real-world applications.

Sensmet's CEO, Dr Toni Laurila, highlighted the trial's importance, stating that the comparison with laboratory ICP-OES data addresses a common query from potential customers. The trial results illustrate the remarkable analytical performance and real-time potential of µDOES® in brine analysis.

Sensmet's patented µDOES® technology utilises atomic emission spectroscopy, employing a micro-discharge to flash-heat a minute volume of the aqueous sample. This process dissociates molecular species into atoms, which, when excited, emit light at characteristic wavelengths. The µDOES® measures this atomic emission spectrum, providing quantitative metal analysis in real-time.

The µDOES® technology, with its continuous measurement capability, offers a user-selectable interval of 5 to 30 minutes, providing consistent high-quality results akin to laboratory analyses. This capability, directly accessible at the process plant, minimises delays associated with lab analyses and maximises the benefits of real-time process monitoring.

More information online

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan