-

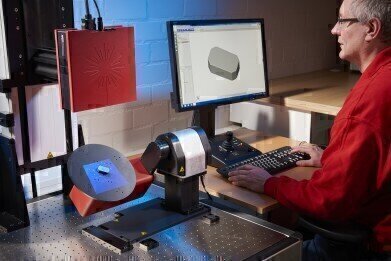

Caption: The measuring equipment the company recently began using offers customers added value by providing insight into the material properties, dimensions and behaviour of a permanent magnet in a particular environment or assembly.

Caption: The measuring equipment the company recently began using offers customers added value by providing insight into the material properties, dimensions and behaviour of a permanent magnet in a particular environment or assembly. -

Mass Spectrometry & Spectroscopy

State-of-the-Art Measuring Equipment Provides Optimal Insight into Magnet Quality

Mar 17 2016

Goudsmit Magnetic Supplies recently acquired an optical 3D scanner and a handheld XRF Analyser. These offer customers added value by providing insight into the material properties, dimensions and behaviour of a permanent magnet in a particular environment or assembly. For example, the three dimensional measurement data from the GOM Atos scanner can show where modifications need to be made to moulds or other tools. In contrast to measuring individual coordinates, as was done with a traditional static CMM machine in the past, the complete geometry and basic shape of an object can now be accurately defined in a polygon mesh. This allows the company to save much more data that is relevant for both their own use and that of their customers.

By laying the image scanned in the GOM Atos over the CAD file the company can see at a glance where modifications are required to moulds or other tools. A colour presentation, labels and cross-sections reveal any deficiencies on the scan. These images are not only clearer but also more precise, because information is provided about the entire product. Moreover, any fitting problems can be detected before assembly and mass production, seeing as how the products under development can be pieced together virtually, in the software. An additional advantage is that the measurement time is just a quarter of what it used to be, which speeds up the testing process and results in a greater volume of valuable data.

The ElementCheck handheld XRF Analyser the company recently began using makes it possible to conduct spectrum measurements for material analysis using electromagnetic radiation. XRF is a process in which a magnet is irradiated with X-ray radiation. This radiation excites the electrons in the elements that are present. When the electrons fall back into their orbits energy is emitted. The released energy, which is characteristic for each element in the magnet, and the quantity of energy are measured to determine the concentration of the elements that are present. The benefits are clear: the QA/QC engineer obtains the desired information in a matter of seconds, as there is no longer any need to send samples to an external lab for analysis. This all takes place in-house, without damage to the product. Moreover, the XRF Analyser gives the company the ability to check and safeguard the quality down to the molecular level.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan