Liquid handling

Simplify Your Liquid Handling Workflows with Automated Positive Displacement

Sep 22 2023

Manual air displacement pipetting is prone to errors leading to variability in results, particularly when handling low volumes. Adjusting pipetting parameters based on the liquid's characteristics and the type of labware being used demands a certain level of expertise that varies from user to user. Although robotic liquid handlers can help eliminate this variability, mostly rely on air displacement, necessitating the optimisation of the same parameters, which affects reproducibility. Positive displacement pipetting effectively addresses these issues and ensures high precision and reproducibility even at low volumes.

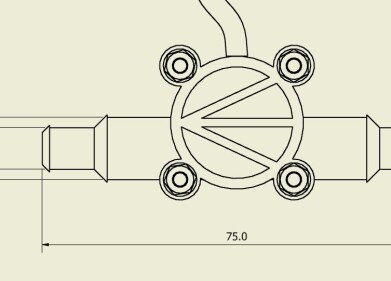

The F.A.S.T. Liquid Handler from FORMULATRIX is a next-generation, low-volume, positive displacement liquid handler. It uses disposable positive displacement tips, like a mini syringe, enabling precise pipetting of small volumes ranging from 0.1 to 13 µL. Each tip has an axially-sealed piston, which directly contacts the liquid, ensuring accurate displacement of the desired volume. This enables the F.A.S.T. to handle liquids with diverse physical properties accurately, making it liquid-class agnostic.

The F.A.S.T. is designed for efficiency and flexibility in liquid handling. Its 96-channel head ensures rapid sample transfer for 96- and 384-well plates, making it a good fit for high-throughput experimentation. It offers the flexibility to select a custom number of tips from 1 – 96. This eliminates the need for multiple pipetting heads for routine lab procedures such as cherry-picking and plate stamping.

To further streamline operations, the F.A.S.T. is equipped with computer vision technology that scans the tip caddy to determine the number and locations of the available tips. Subsequently, the head automatically rearranges tips as per the protocol requirements, eliminating the tedious task of manual tip sorting. Additionally, the system prompts users to replace the tip caddy if insufficient tips are available for the intended run.

The F.A.S.T. also incorporates a built-in touch probe to define the labware geometry being used by measuring it in place on the system. The user only needs to provide information about the number, shape, and type of plate wells, after which the touch probe automatically measures the well width, depth, and plate height. This innovative feature eradicates the need for manual measurements, saving time and preventing potential errors.

A removable tray, capable of holding up to five SBS-format plates and a tip caddy, is another feature that enhances F.A.S.T.'s utility. Interchangeable trays allow users to pre-set tips, plates, and reagents while the instrument is executing a run. Each tray is barcoded and calibrated individually with all the unique tray settings stored in the software. This convenient setup allows users to have multiple trays, each configured for a different experiment, thereby minimising downtime associated with instrument setup.

The F.A.S.T. requires no programming expertise or extensive training, functioning similarly to a multi-channel pipette for simple transfers. Predefined higher-level functions, including serial dilution, normalisation, plate broadcasting, and pooling, extend F.A.S.T. versatility, making it well-suited for various laboratory applications. The user-friendly interface is designed for any level user in the lab which means less time is needed to train staff on how to use the system.

Contact FORMULATRIX today to learn how to simplify liquid handling in your lab.

More information online

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan