Laboratory products

Comprehensive range of high-quality tube furnaces

Feb 01 2022

The product specialists, engineers and designers at Carbolite Gero, part of the Verder Scientific group of companies, have worked tirelessly to develop a new range of tube furnaces boasting high-quality heating elements and innovative thermal insulation which deliver unrivalled performance with rapid heating & cooling, outstanding temperature uniformity and significantly reduced power consumption. They can all be used either horizontally or vertically. Their solid construction and high-quality components ensure users will benefit from a significant return on their investment.

Whether you require a single or three-zone universal tube furnace [TF Range], a split tube single or three-zone furnace [TS Range] or a gradient tube furnace [TG Range] with two or three heated zones, the comprehensive range of tube furnaces from Carbolite Gero are outstanding solutions for your organisation. For more specific requirements the TSO rotary / oscillatory reactor tube furnace and the TSR rotary tilt furnace have been incorporated significant customer feedback to ensure unrivalled versatility.

These new furnaces have various mounting configuration options. For heated lengths up to 600mm the furnace body is mounted on top of the control box. The furnace body can easily be detached and separated for remote operation. For heated lengths of 800 mm and above the furnace body and control box are always separate. Both configurations include a 2-metre cable (incl. plug and socket) between the furnace body and control box. This flexible arrangement allows for easy conversion to optional mounting arrangements e.g., attaching to a vertical stand, a mounting bracket or inside a fume cupboard.

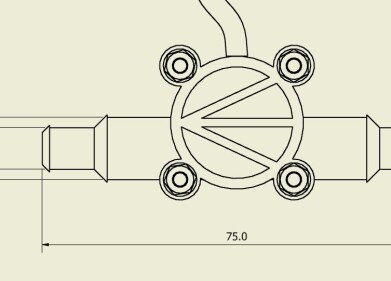

Carbolite Gero's TSO rotary / oscillatory reactor tube furnace has been specially designed for the processing or testing of powdered or granular materials at high temperatures. A quartz vessel is fitted within the furnace into which materials are placed. A variable speed drive system rotates the vessel within the heated zone by 314° to create an oscillatory motion. It can be equipped with gas connections to accommodate modified atmosphere applications.

Carbolite Gero's TSR rotating tube furnace range helps increase the surface area of the sample material exposed to the atmosphere within the work tube, helping to speed up reaction times and improve the overall yield. It comprises a split tube furnace horizontally mounted on a base frame, and fitted with a friction drive rotation system, allowing for work tube rotations of up to 10 rpm. The frame can be manually tilted up to a maximum angle of 6Ëš and a 5-litre capacity vibratory feeder and collection hopper makes it the ideal choice for continuous heat treatment processes.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan

.jpg)