-

Lauda Variocool process thermostats are ideal for controlling the temperature of bioreactors in the manufacture of pharmaceuticals.

Lauda Variocool process thermostats are ideal for controlling the temperature of bioreactors in the manufacture of pharmaceuticals. -

-

A major customer from the pharmaceutical sector uses Variocool process thermostats with NRTL certification to manufacture Covid-19 vaccines.

A major customer from the pharmaceutical sector uses Variocool process thermostats with NRTL certification to manufacture Covid-19 vaccines.

Laboratory products

Using Temperature Control Technology in the Fight Against COVID-19

Apr 26 2022

Lauda secures major order for the delivery of Variocool process thermostats with NRTL certification

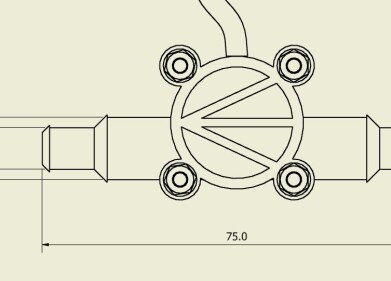

Lauda has secured a major order for Variocool process thermostats. The German subsidiary of a major global US company in the biopharmaceutical sector has ordered a total of 76 devices, including accessories, for integration in their systems for producing the Covid-19 vaccine. The different models have a cooling capacity of between 2 and 10 kW.

The Variocool process thermostats are factory-certified according to CE and NRTL, and therefore meet the standards required in Europe as well as in North America. Lauda redesigned these flexible devices before launching them onto the market in November 2020. The process thermostats have bi-frequency and multivoltage capability, which means that if production is relocated, the thermostats can be easily transferred to another location and also make project planning easier for the customer.

Lauda has scheduled delivery of the ordered Variocool process thermostats to the customer for the end of April 2021. The customer uses Lauda devices for controlling the temperature of mixers and single-use bioreactors required to manufacture Covid-19 vaccines. Cell cultures are grown at a temperature of between 4 and 37°C in reactors with a volume of between 200 and 2,000 litres. Variocool process thermostats are designed to maintain a stable temperature within an extremely narrow tolerance range of ± 0.1 K.

Last year, Lauda significantly increased its production capacity for Variocool process thermostats due to the high demand, and was therefore able to meet the tight delivery deadline. "Lauda had already been working closely with the Variocool process thermostat customer for several years even before the major order was secured," explained OEM sales specialist Tobias Henning, who is responsible for OEM customer support in the bioprocessing sector. The Lauda OEM division helps customers develop complete systems by establishing standards in collaboration with the relevant development teams, which are then integrated into the product configurator of the OEM customers at a later stage. As a result, the customer also receives assistance with documentation, calculations and similar tasks. In some cases, the OEM division even develops devices specifically for customers. "We are currently seeing a high degree of satisfaction with Lauda on the market and want to build on this trust as a basis for further expanding our capacity to cater for specific customer developments," explained Thorsten Eilers, OEM Managing Director at Lauda.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan

.jpg)