-

Versafreeze product range already includes ultra-deep freezers and cabinets of various sizes.

Versafreeze product range already includes ultra-deep freezers and cabinets of various sizes. -

The battery-powered Mobifreeze ultra-low temperature freezer.

The battery-powered Mobifreeze ultra-low temperature freezer. -

CEO Dr Gunther Wobser presents the Mobifreeze at Analytica 2022.

CEO Dr Gunther Wobser presents the Mobifreeze at Analytica 2022.

Laboratory products

Ultra-High-Quality, Ultra-Safe, Ultra-Reliable - and soon mobile!

May 24 2023

What demands do you have...

... for the storage of your biological samples, valuable pharmaceuticals, and chemical concentrates? Safety and security? Durability? Energy efficiency? Lauda has an answer to these requirements: the Versafreeze (ultra) freezers and chest freezers. Vaccines, organic substances, and valuable samples that need to be stored at low temperatures represent irretrievable assets. To protect them from warming, Versafreeze units use a combination of vacuum insulation panels, thermofoil, and diffusion-resistant foamed polyurethane insulation. This high-grade combination enables economical energy consumption, excellent temperature homogeneity, and consistency, as well as short pull-down and maximum warm-up times. The insulation is also thinner with the same or even improved properties, leaving more space for the cooling chamber. In the design, Lauda relies uncompromisingly on top-quality components such as vacuum panels from va-Q-tec, compressors from Embraco, or controllers from Störk. After all, quality and reliability - and therefore the safety of valuable samples - are Lauda's top priorities for its deep freeze appliances.

The Versafreeze units allow storage temperatures as low as -86°C and also feature sophisticated safety technology: whether in the event of a power failure or to protect against unauthorised access.

But what about transport?

In numerous scenarios, temperature-sensitive products not only have to be stored but also transported: from one hospital building to another, from plant location A to plant location B, from production to storage, or from storage to filling. Depending on the sample, pharmaceutical, or concentrate, precisely defined temperatures must be kept throughout the process. Many of these transports are currently made possible either by dry ice (-78.5°C) or phase change materials (-30°C). There is little leeway between these temperatures, but the European Commission's GDP (good distribution practice) guidelines, for example, require that pharmaceutical products be transported at ideal storage temperatures. In addition to the temperature challenges, there are also hazards that arise from handling dry ice (including health hazards/asphyxiation hazards if the dry ice evaporates, and cumbersome handling of large quantities, and more).

The solution

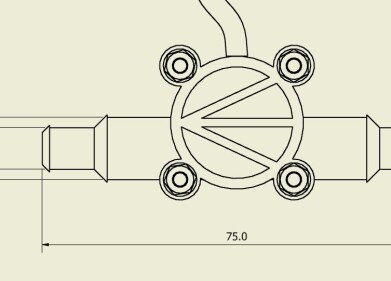

Lauda presents the mobile ultra-low temperature freezer Mobifreeze! The temperature control unit manufacturer already presented the prototype at Analytica 2022, and the innovation will finally be available in series production in late summer of this year. The ultra-deep-freezer comes with a powerful battery (lithium iron phosphate battery technology), which allows a runtime of up to three hours at a working temperature of -80°C. The battery charging time is three hours during operation. With a working temperature range of -86°C to -50°C and a usable space of 270 L, Mobifreeze offers plenty of scope for your requirements. Moreover, mobility has been considered not only regarding battery operation. 360° rotating heavy-duty castors and ergonomic handles guarantee excellent manoeuvrability.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan