-

The Disk Mill PULVERISETTE 13 premium line in combination with Fritsch high-performance Cyclone separator.

The Disk Mill PULVERISETTE 13 premium line in combination with Fritsch high-performance Cyclone separator. -

The Disk Mill PULVERISETTE 13 premium line with large funnel, smooth inner surfaces and flow-optimised transition areas for optimal material feeding.

The Disk Mill PULVERISETTE 13 premium line with large funnel, smooth inner surfaces and flow-optimised transition areas for optimal material feeding.

Laboratory products

Efficient Premium Fine Grinding

Jul 19 2022

Easy operation, reproducible results

Fritsch’s Disk Mill PULVERISETTE 13 premium line grinds hard-brittle to medium-hard solids down to 0,05 mm fineness. It is ideal for medium particle sizes in the areas of mining and metallurgy, ceramics industry, rocks and soils, glass industry, soil research.

The instrument is especially safe due to the automatic locking of collecting vessel and grinding chamber. And thanks to the simple motor-driven grinding gap adjustment with digital gap display and the presentation of all parameters on the well-designed display are absolutely convenient to operate.

The extra powerful motor provides high throughput of up to 150 kg/h. Fast, residue-free cleaning is ensured due to the smooth grinding chamber, inner surfaces, removable funnel and labyrinth sealing of grinding chamber. This Clean Design also protects against sample contamination.

The grinding disks can change the rotational direction (clockwise/counter-clockwise) thereby extending the service life. Grindings disks are available in 4 different materials for optimal adaptation to your sample material. The connection of a dust exhaust system, directly controlled via the instrument, enables dust-free grinding.

Strong team: Disk Mill plus Cyclone separator

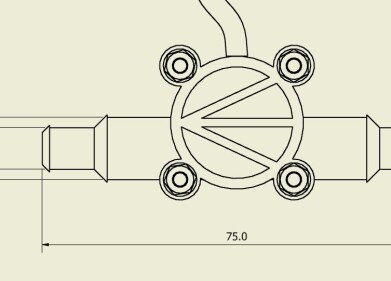

Now the Fritsch Disk Mill P-13 premium line can be combined with the high-performance Cyclone separator. This not only simplifies filling and cleaning considerably, but at the same time finer gap widths for higher final fineness can be used without any problems. The strong airflow of the Cyclone separator accelerates the throughput, increases the discharge from the grinding chamber and keeps the thermal load of the samples low, even with materials such as coal or chalk, which are otherwise difficult to grind finely. At the same time, the output of the sample can be actively controlled, and the fine dust load in the vicinity of the mill remains significantly lower. The comminuted sample is fed directly into a screw-on glass and no longer has to be laboriously transferred manually from the drawer.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan

.jpg)