Laboratory products

The Rotational Viscometer with the Highest Traceability on the Market

Jul 12 2023

Quality control in production ensures satisfaction of specified quality requirements for products or intermediate products. Measuring instruments can be engineered close to perfection so hardly any errors occur in testing to determine consistent quality. Where errors can occur, though, is in the operation of these instruments. It is therefore crucial to prevent operator errors to the greatest extent possible. If an operating error does occur, it should ideally be as traceable as possible so the problem can be resolved quickly, minimising costly downtime of the production plant.

Maximising traceability, minimising user error

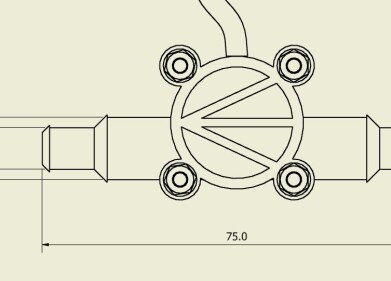

Anton Paar's ViscoQC series of rotational viscometers offers a number of features that help prevent viscosity measurement errors and make measurements fully traceable.

A prime example is the unique ToolmasterTM feature for automatic spindle-type recognition: All spindle data is delivered to the viscometer as soon as the spindle is magnetically attached. That way it is impossible to select the wrong spindle from the usual spindle list. With ViscoQC 300, you can restrict each measuring method to a unique spindle identity. No time is wasted with repeat measurements (e.g., if the wrong spindle was mistakenly chosen).

ViscoQC detects all attached accessories and documents them in the final measurement report:

- Magnetic coupling spindles via ToolmasterTM and spindle guard via TruGuardTM

- Peltier Temperature device PTD 80 – for fast and accurate control of sample temperature (15 °C to 80 °C)

- PTD 175 – high-performance temperature control, suitable for standards like ASTM D2983/D8210/D5133/7110 and DIN 51398

- PTD 100 Cone-Plate – for small sample volumes from 0.5 mL to 2 mL

- Heli-Plus – for non-flowing substances like gels, pastes, and creams

All these accessories are operated entirely via the ViscoQC display, greatly increasing the ease of use and facilitating automatized measurements with self-created methods, thereby also reducing measurement errors and improving repeatability.

Another feature, built-in digital leveling, constantly monitors and displays the correct leveling status and ultimately also indicates it in the measurement report. Consistently correct leveling significantly increases the repeatability of the measurement and ensures superb accuracy.

Achieve full compliance in just one day

The top-notch traceability associated with ViscoQC also makes it the perfect choice for pharmaceutical customers. Upgrade with the V-Comply software (unlocking features like audit trail, electronic signature, compliance modes, increased security functions, and more), benefit from a comprehensive qualification package, and achieve compliance with 21 CFR Part 11, GMP, and GAMP 5 – in just one day.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan