-

-

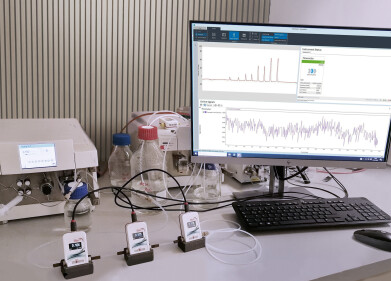

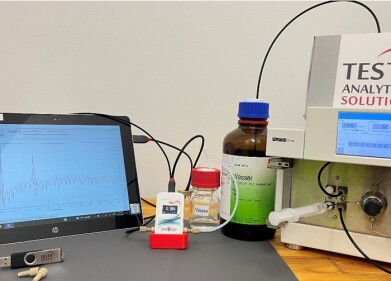

Alexandre Berteletti, Leman Instruments.

Alexandre Berteletti, Leman Instruments. -

Chromatography

High Technology Gas Generators for Every Application

May 15 2020

Leman Instruments has developed rapidly to become a leading European company specialising in the field of high technology gas generators.

The specialist modules of scientific equipment concentrates on the provision of standard products, OEMs and in custom designed realisation involving high purity Hydrogen (H2), Nitrogen (N2), Zero Air and combined solutions for FIDs, GCs, purge air generations, CH4 and CO2 scrubbers, N2 and multi gas for LCMS.

Individually equipped with high performance communication interfaces (RS485, Ethernet and WLAN options), the reliable instruments significantly reduce operational costs and provide a solid return on investment within the space of two years. Suitably slotting into laboratory, air quality monitoring and industrial environments, the apparatus has been strategically constructed to suit the majority of these related applications.

These premium quality modules also provide high pressure stability, essentially improving upon the resolution and detection limits of instruments, whilst the constant purity ensures there will be no contamination concerns. Integrating Proton Exchange Membrane (PEM), Pressure Swing Absorption (PSA) and Catalysis technologies, they can be easily controlled via a touch panel or iPad, proving incredibly easy to install and operate.

One of Leman Instruments’ newest innovations is its combined technology gas generator, the GC Station 60LC. The single unit incorporates an inboard compressor and is a concept unlike any other currently offered in the marketplace.

Another notable product from Leman Instruments is the range of Hydro 50ml/min to 15 l/min High Purity Hydrogen Generators for FID and Carrier Gas to fit almost any type of application which needs High purity H2 production close to the consumer in laboratory environment.

Based on the field proven Solid Polymer Electrolyte (PEM) cell technology, pure Hydrogen is produced at low pressure from electricity and high quality distilled water (Zero Water). This process can be started on demand and does not require any caustic solution. The produced Hydrogen is available 24/7 with constant minimum purity superior to 99.995% and maximum at 99.99995% at output flows of 50ml/min to 15 l/min (depending on the model.) The H2 output pressure is regulated electronically and can be set from 0.5 to 10 bar. (7 to 140 psig).

More information online

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan