-

The Variable Speed Rotor Mill PULVERISETTE 14 classic line.

The Variable Speed Rotor Mill PULVERISETTE 14 classic line. -

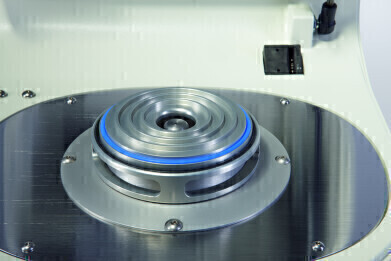

Efficient air cooling of the rotor.

Efficient air cooling of the rotor. -

The Fritsch small volume Cyclone separator.

The Fritsch small volume Cyclone separator. -

The Fritsch high-performance Cyclone separator.

The Fritsch high-performance Cyclone separator.

Mills and Grinders

The Ultimate Mill for Diverse Samples

Feb 07 2023

One mill, many possibilities

The PULVERISETTE 14 classic line from Fritsch is the perfect mill for efficiently grinding soft to medium-hard, brittle, fibrous, and temperature-sensitive materials. With its variable speed rotor, this mill has been proven worldwide for trace analysis applications.

The motor speed of the PULVERISETTE 14 classic line can be adjusted in 1,000 RPM increments between 6,000 and 20,000 RPM, allowing for tailored performance to each application. An automatic speed compensation function optimises the grinding process by adapting to the specific comminution behaviour of the sample. The efficient air routing within the mill also minimises thermal strain on the sample, ensuring fast and effective grinding.

Efficient cooling

The PULVERISETTE 14 classic line features an innovative air routing system that maintains a constant flow to cool the rotor, motor components, and grinding material in the collection vessel. The mill also features a large fan that blows filtered cooling air into the instrument, creating positive pressure and protecting against the entry of dirt particles from the surrounding air.

Fritsch Cyclone separators: fine grinding for temperature-sensitive materials

When paired with the Fritsch Cyclone separators, the PULVERISETTE 14 classic line is ideal for ultra-fine grinding of temperature-sensitive materials, as well as for pre-crushing and fine-grinding of hard-brittle to soft samples with residual moisture. The compact, plastic Fritsch small volume Cyclone separator can be easily disassembled and cleaned in a dishwasher. The comminuted sample is collected in a screw-on sample glass. Additionally, the small volume Cyclone separator can be used with the included 80-100 µm fine-dust filter for passive use or in conjunction with an exhaust system.

Constructed entirely from stainless steel 304, the Fritsch high-performance cyclone is essential in the analytical sector, food industry, and pharmaceutical industry. When used in combination with the exhaust system, it provides exceptional performance. The exhaust system to operate the Fritsch cyclones can be purchased separately.

The efficient air routing within the PULVERISETTE 14 classic line and the strong air vortex of the Fritsch Cyclone work together to cool the sample during grinding, reducing thermal stress and minimising clogging of the sieve rings, resulting in increased throughput. Cleaning of the mill is also kept to a minimum. The air flow in the Fritsch Cyclone directs the ground sample directly into the collection vessel, which is the most convenient method of sample discharge. The ground material is collected in a glass bottle for easy transport, storage, and removal for analysis.

More information online

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan