Microscopy & Microtechniques

Encapsulated Multilayer Actuators with improved Heat Dissipation

May 20 2014

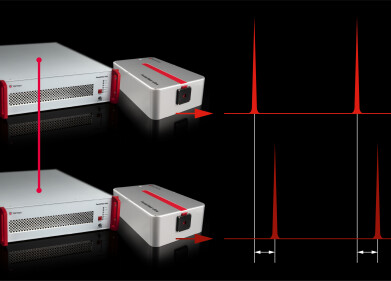

In extreme operating conditions, where oil, splash water or continuously high humidity prevail, the stainless steel encapsulated multilayer piezo actuators ensure the required reliability and lifetime. But if the PICMA® actuators are to be used for dynamic applications at the same time, the self-heating of the actuator can be a limiting factor.

For this purpose, PI Ceramic now offers encapsulated actuators with improved heat dissipation properties: A casting compound that does not impair the actuator displacement replaces the inert gas in the hollow space between metal bellow and piezo actuator.

Additional cooling of the stainless steel casing, e.g. with compressed air or water, can help to dissipate the heat generated by the dynamically operating actuator. This allows to achieve working frequencies that are 10 times higher than with an actuator without casting compound, for example, up to 3.5 kHz with the P-885.95 over the full travel range of 36 µm.

PI Ceramic produces the encapsulated multilayer piezo actuators in the sizes Ø 11.2 mm × 40.5 mm for 30 µm travel and Ø 11.2 mm × 22.5 mm for 14 µm travel. Higher forces can be achieved with a version measuring Ø 18.6 mm × 22.5 mm providing a minimal displacement to 14 µm. For these dimensions, the actuators with casting compound are available at short notice. On request, the encapsulated PICMA® stack multilayer piezo actuators can be manufactured in other sizes.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan

.jpg)