Microscopy & Microtechniques

Rapid inspection and characterisation of alloys using the Phenom desktop SEM

Oct 07 2015

The properties of many engineering materials are mostly governed by a combination of their composition, morphology and distribution of key micro structural features. These features can be observed with a range of imaging techniques, each with their own strengths and weaknesses. Scanning electron microscopy (SEM) is best suited when more detail is required such as higher three dimensional magnification. Viewing three dimensional images of microscopic areas only solves half the problem in an analysis. It is often necessary to also identify the different elements associated with a specimen. Integrating electron imaging (SEM) with X-ray analysis is a very powerful combination for understanding the composition and structure of materials.

For example, X-ray analysis can be important when monitoring a production process that needs to create a consistent material mix such as the fabrication of alloys and ceramics. SEM imaging of a sample from production can reveal contamination with an unknown substance or the inclusion of unknown particles. With integrated X-ray analysis these particles can be examined and their composition and potential origin easily revealed.

The Phenom desktop SEM is affordable, easy to operate and offers direct access to the high-resolution and high-quality imaging and elemental analysis of micron and submicron structures necessary in a large variety of applications. With the Phenom integrated X-ray analysis system, rapid examination of common engineering alloys (e.g. Al, Ti, Fe and Ni) can be performed in areas such as routine metallurgical analysis, quality control, failure analysis, and research studies.

Metallurgical inspection with Phenom SEM

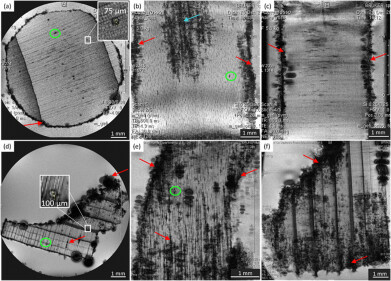

Metallography provides information about an alloy linking its composition and processing to its properties and performance. For example, in titanium alloys the yield strength has been shown to be related to the thickness of the α-laths. Precise measurement of the α-laths is important for input into emerging models that are capable of predicting alloy properties. Figure 1 shows the α-laths (darker phase) as well as the β-ribs (lighter phase) between the laths of β-processed Ti-6-4. Using established measuring techniques it is possible to calculate the average thickness of these laths with an uncertainty of approximately 50 – 100 nm, which is less than the resolution limit afforded by conventional optical microscopes (i.e. 200 nm). Often in titanium alloys there is a second nucleation event that will result in the formation of sub-micron sized α-laths (e.g, secondary alpha) as shown in Figure 2.

Additional microstructure observations of a cast aluminum alloy are shown in Figure 3 and Figure 4. The size and distribution of the intermetallic phases (lighter phases) and shrinkage porosity impacts the alloy properties. Figure 3 illustrates an important feature of the Phenom – the ability to gather topological information (e.g. details of the shrinkage porosity) due to the intrinsic depth of focus, while concurrently collecting information about the distribution of phases within the microstructure indicated by contrast variations in the image. Ni-based superalloys are an excellent example of an 'engineered' alloy, and the current state-of-the-art alloys are the product of decades of development.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan