-

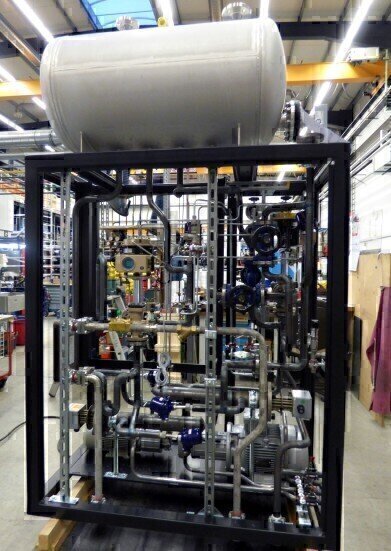

The Lauda heat transfer system just prior to placement in the safety glass enclosure at the Max Planck Institute in Magdeburg.

The Lauda heat transfer system just prior to placement in the safety glass enclosure at the Max Planck Institute in Magdeburg. -

The heat transfer system was adapted to the special requirements of the customer. The image shows the open system. All lines are thermally isolated prior to delivery.

The heat transfer system was adapted to the special requirements of the customer. The image shows the open system. All lines are thermally isolated prior to delivery. -

The restricted on-site conditions and special requirements of the researchers were taken into consideration during the system design phase. The Max Planck Institute is extremely pleased with the services provided by the manufacturer.

The restricted on-site conditions and special requirements of the researchers were taken into consideration during the system design phase. The Max Planck Institute is extremely pleased with the services provided by the manufacturer. -

The Max Planck Institute is using the Lauda system to research energy storage processes. The system must be capable of controlling the temperature precisely to 150°C.

The Max Planck Institute is using the Lauda system to research energy storage processes. The system must be capable of controlling the temperature precisely to 150°C.

Laboratory Products

Temperature Control for Future Energy Storage Systems

Jul 10 2019

Lauda Heating and Cooling Systems have developed a type ITH 350 heat transfer system for the Max Planck Institute. The system is used to control the temperature of a reactor. The Lauda system must be able to provide cooling of 100 Kelvin per minute without falling below the end point. It must therefore cool down quickly but must not fall below a certain temperature point and endanger the actual process. The research carried out at the Max Planck Institute requires a system that cools extremely quickly.

A methanation reaction generates a great deal of heat and high temperatures that may damage the reactor, or more importantly, the catalyst. During the process, the reactor is heated electrically to 340°C. Once a defined temperature is reached, an exothermic reaction is triggered and the system must then be rapidly cooled to 150°C. An electronic valve used in normal situations that serves as a regulating device would be much too slow for this particular application. Lauda engineers therefore developed a pneumatic 3-way valve that opens in only 2 seconds to ensure that the heat carrier is cooled at more than 150°C per minute.

The heat transfer system incorporates two thermostatic circuits. While the first circuit controls the temperature in a buffer vessel, the second circuit controls the temperature in the test setup of the Max Planck Institute. Both circuits use the same medium and are connected to one another via the media storage unit. One additional customer requirement for the system was that the heat carrier could be used at temperatures of up to 350°C. Lauda selected a thermal oil capable of satisfying the demanding requirements of the material.

Lauda developed and designed the special heat transfer system according to the requirements of the Max Planck Institute. The system had to be enclosed in a special safety dome, which made it necessary to mount the control cabinets on the side. The Lauda system was sent to Magdeburg for assembly in two parts, which were lifted into the safety glass enclosure by a crane.

This heat transfer system for methanation research was the second system Lauda has delivered to the Max Planck Institute. The institute is extremely satisfied with the services provided by the temperature control manufacturer.

More information online

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan

.jpg)