Laboratory Products

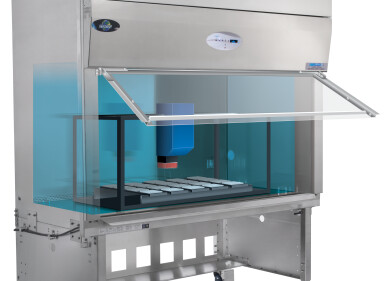

Variable Speed Rotor Mill suitable for Fine Grinding of Temperature-Sensitive Samples

Nov 03 2014

The Fritsch Variable Speed Rotor Mill PULVERISETTE 14 grinds rapidly and effectively soft to medium-hard, brittle as well as fibrous samples. Due to its very efficient air-cooling and the cyclone, even the comminution of difficult to grind samples like temperature-sensitive powder coatings and plastic samples or slightly moist materials such as herbs, leaves or teas are no problem for the PULVERISETTE 14.

The efficient air routing inside the PULVERISETTE 14 and the powerful air vortex within the Fritsch Cyclone cools the sample during grinding, reduces the thermal load of the sample and minimises clogging of the sieve rings while simultaneously increasing the throughput significantly. Cleaning the mill itself is reduced to a minimum. The airflow inside the Fritsch Cyclone leads the ground sample directly into the screwed-on sample glass. This type of sample discharge is the most convenient, because the ground material is drawn directly into the glass bottle where it can be transported, stored and easily removed for analysis. Thereby, the fine dust is retained in the cyclone by the HEPA dust filter and results in increased performance for particularly fast and effective grinding that minimises the thermal load. This makes it the ideal solution for especially heat-sensitive materials, as well as for smooth pre-crushing and fine grinding of hard-brittle to soft, fatty or samples with residual moisture.

Extremely difficult to grind or acutely temperature-sensitive samples like styrene, polyester, synthetic resins, foils, PVC, PP and PE can be embrittled by adding liquid nitrogen and afterwards ground with the PULVERISETTE 14.

Further advantages include: variable speed adjustment from 6,000 to 20,000 rpm; max. feed size 10 mm, throughput 0.05 up to 5 l/h, also ideal for minimal sample quantities: 5 – 10 ml; final fineness d50 < 40 µm, sieve inserts 0.08 – 6 mm; automatic rotational speed readjustment system for constant grinding; grinding parts made of stainless steel, pure titanium, TiN-coated and WC-coated; rapid-action clamping lock.

Digital Edition

International Labmate 49.6 - Sept 2024

September 2024

Chromatography Articles - HPLC gradient validation using non-invasive flowmeters Mass Spectrometry & Spectroscopy Articles - From R&D to QC, making NMR accessible for everyone: Putting NMR...

View all digital editions

Events

Oct 06 2024 Liverpool, UK

Oct 08 2024 Gothenburg, Sweden

Oct 09 2024 Birmingham, UK

Oct 09 2024 NEC, Birmingham, UK

Oct 15 2024 Milan, Italy

.jpg)