Laboratory Products

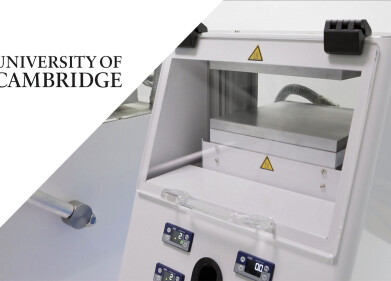

Captair Flex : safety, performance and energy savings

Oct 05 2011

The Captair Flex (1) line can be configured to the protection needs of laboratories. By combining molecular and HEPA H14 filtration technologies, the Flex technology allows the user to do a very large variety of liquid handlings such as dilutions, titrations, extractions, transfers, solid handlings such as sieving, grindings, weighings, formulations, compressions, to combinate liquids and solids for dissolutions, filtration and extraction. This new line can also be adapted to the lab environment such as clean rooms up to class ISO 5 classification.

Filtration technologies used in the design of captair® Flex® non ducted filtration fume hoods enable to protect laboratory users but also to protect the environment : Since no ductwork is required, it totally eliminates the direct discharge of pollutants into the atmosphere, reduce carbon footprint as it does not generate any pollution linked to energy production unlike a traditional ducted fume hood. Its installation is quick and easy. There is no need for a ductwork linked to an air supply / air extraction system, in comparison to traditional ducted systems. Its setting up can be realized at any time, without any complex forward planning. Users can also benefit from the use of an immediately available unit, easy to relocate without disturbing room air balance.

This ductwork air balance, essential to the proper operation of a traditional ducted fume hood however is also the source of very important energy consumption. Captair® Flex® filtered enclosures do not generate any energy costs associated with the use of expensive extraction systems or conditioned air supplies. Operational costs can, by consequence, remain at a minimum even when taking into account filter changes.

The compliance of the captair® Flex® range with the 2009 AFNOR NF X 15-211(2), the major standard related to ductless filtering fume hoods insures users real performance criteria with regards to : Filtration efficiency (the emission concentration at the filter exhaust must be lower than 1% of the handled product TLV), Containment (the maximal concentration of of SF6 tracer gas at the measuring points as described in the standard procedure is 0.1 ppm) and the air face velocity (the air face velocity at any point of the front openings must be between 0.4 and 0.6 m/s).

Associated with the Erlab Safety Program (3) (ESP), an exclusive qualification service offered for each unit, laboratories can benefit the 40 years experience of Erlab in offering alternative protection devices for laboratory technicians against chemical hazards.

Digital Edition

Lab Asia 31.4 August 2024

August 2024

Chromatography Articles - HPLC gradient validation using non-invasive flowmeters Mass Spectrometry & Spectroscopy Articles - MS detection of Alzheimer’s blood-based biomarkers Labo...

View all digital editions

Events

Sep 11 2024 Bangkok, Thailand

Sep 11 2024 Bangkok, Thailand

Sep 11 2024 Singapore

Sep 18 2024 Lausanne, Switzerland

Sep 19 2024 Shanghai, China

.jpg)