Laboratory Products

Special Furnace is Cost-Effective Solution for Crystal Growth

Dec 29 2015

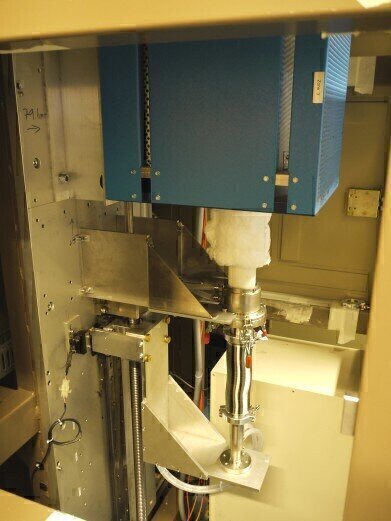

The Department of Physics at the University of Warwick, which is at the forefront of research into the properties of new and exotic materials, has increased its crystal growth capabilities with the installation of a multi-zone Bridgman furnace from Carbolite Gero in the superconductivity and magnetism research laboratories.

Close collaboration between the company and university staff has enabled the new furnace to be integrated with gas, chilled-water, blower and control systems already in place for use with a previous unit, significantly reducing the cost compared with installing a complete Bridgman unit with all associated accessories.

The Warwick University physics department has been producing single crystals of a very wide range of materials for over 20 years, meeting demand for specimens for studying the physics of condensed matter within UK laboratories. The Warwick team working in this field uses a variety of equipment to produce high-quality specimens of oxides, selenides, silicides, borides, inter-metallics and related materials.

The Carbolite Gero Bridgman unit has a maximum temperature of 1350ºC, which is considerably higher than previous equipment in the laboratory and allows the department to make further advances in its work on superconductors and the newly discovered topological insulators. The furnace incorporates a 1200mm-long vertical work-tube with three 250mm heating zones, allowing specific temperature gradients to be created.

The furnace itself has been installed within an existing frame and uses the previous loading and unloading procedures, which involve inserting vacuum sealed quartz ampoules containing the samples into the top of the work-tube and lowering them to the bottom on a platform at precise speeds. Each procedure typically takes one to four weeks, during which the materials melt together and solidify to form the desired crystal.

Heating is provided by 5mm wire elements linked to a type-S thermocouple and powered by a low-voltage supply via a heavy-duty transformer that together provide very accurate temperature stability and greatly increased element life. Low-thermal-mass insulation minimises heat loss and energy consumption and also allows high heating rates.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan

.jpg)