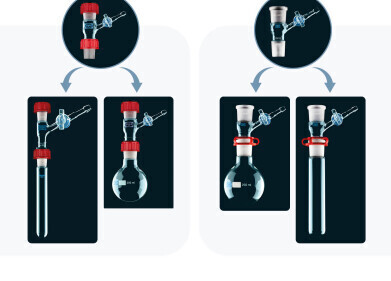

Glassware

Why Pyrex®?

Sep 03 2019

Pyrex® glassware has been manufactured in the UK since 1923. SciLabware has gained almost a century of expertise, experience and knowledge in the manufacturing processes and techniques required to manufacture laboratory glassware to a consistently high quality. By the continual monitoring of manufacturing processes and procedures, we ensure that products are manufactured to comply with the highest product standards.

Here are just some of the many features of Pyrex® laboratory glassware that makes it the obvious choice for your laboratory:

Excellent temperature properties – The quality of manufacture of Pyrex® glassware makes products safe to use over a very wide temperature range (-192oC to +500oC) and hence suitable for a variety of applications. Glass can break very easily when subjected to heating or cooling. The high silica content (over 80%), gives Pyrex® glass a low co-efficient of expansion (3.3x10-6K-1). This means that the glass is less likely to break, as it expands or contracts very little when heated or cooled. This makes it safe to use over a very wide temperature range.

High chemical resistance - Pyrex® borosilicate glass is extremely chemically resistant to most acids, alkalis and solvents so is safe and durable to use in a wide range of laboratory applications.

Uniform wall thickness - When heated, the uniform wall thickness of Pyrex® glassware permits the even distribution of heat throughout the vessel allowing the glass to expand at a stable consistent rate, thus reducing the risk of breakage and extending product life. Glassware with an irregular wall thickness is more likely to break when heated, as the thicker and thinner areas of glass will heat up and expand at different rates causing uneven heat transmission and the glass to crack – this is known as thermal shock. Thermal shock is one of the main contributing causes of glass breaking when being heated and is a major safety risk to users.

Properly annealed glass - Reduces the risk of breakage due to thermal and mechanical shock (minor knocks sustained during use), thereby extending the service life of the glassware. Annealing is a critically important process in the manufacture of Pyrex® glassware whereby the glass is slowly passed through a long oven (known as a Lehr) which heats it up and then cools it down in a slow controlled manner (Pyrex® glass is heated to +565°C and then slowly cooled to ambient temperature). This process relieves any residual internal stresses in the glass introduced during the manufacturing process, thus reducing the risk of breakage due to thermal and mechanical shock. Inadequately annealed glass products are likely to crack or shatter when subjected to even small temperature changes or knocks.

For more information on the SciLabware Pyrex® laboratory glassware range and to learn more on how it can help you in your work please click here.

Digital Edition

Lab Asia 32.2 April

April 2025

Chromatography Articles - Effects of small deviations in flow rate on GPC/SEC results Mass Spectrometry & Spectroscopy Articles - Waiting for the present to catch up to the future: A bette...

View all digital editions

Events

Apr 22 2025 Hammamet, Tunisia

Apr 22 2025 Kintex, South Korea

Analytica Anacon India & IndiaLabExpo

Apr 23 2025 Mumbai, India

Apr 23 2025 Moscow, Russia

Apr 24 2025 Istanbul, Turkey