Glassware

Using a laboratory glassware washer to perform pasteurisation

Mar 03 2014

Named after Louis Pasteur, the process slows spoilage in food and drink, caused by microbial growth. The product is heated to a specific temperature for a defined length of time before being quickly cooled.

Pasteurisation is a thermal treatment applied to foods to remove and destroy pathogens. In the food and drinks industry, tunnel washers are often used to pasteurise drinks bottles in a production line. Within R & D flavour laboratories, new flavours and additives are tested for heat stability prior to being used in new formulations and production. Typically, pasteurisation here is performed with a bench top pasteurisation system, in a stove-top immersion bath.

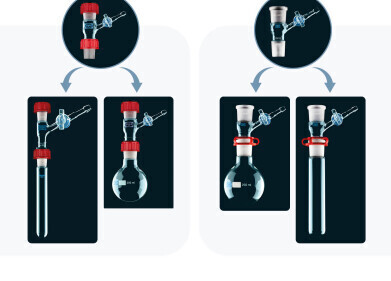

In terms of machinery, the Miele Professional PG8535 glassware washer can be used instead of a typical immersion system or tunnel washer to pasteurise. The PG8535 simulates tunnel washer conditions on a smaller scale, so. bottles are sprayed with water at a specific temperature but stay in place in the wash chamber. With the PG8535, temperatures can be raised step-by-step then held for a specific time interval and then lowered. This temperature ramping can be customised for a particular liquid, volume or flavour, to ensure that these are not altered or affected by the process. For example, the program can be written with a number of steps, with each step raising the temperature gradually degree Celsius by a degree Celsius then holding the temperature for a given time designated by the responsible user operating the machine. Since the programming is easily done using the electronic control of the PG8535, optimal hold times and temperatures can be determined with minimal testing. Miele Professional also provides onsite training in the operation of the machine and custom programming using temperature sensors in the vessels to be pasteurised determining a pasteurisation program for any customers.

The holding times and temperature can be customised allowing for researchers to optimise the flavour. For example, if the material is heat sensitive, the water temperature can be held at a lower level for a longer time. Once the temperature is held, it must then be ramped down to cool the bottles.

To find out more about how Miele Professional can help your business, phone 0844 8936907 or visit http://www.miele-professional.co.uk/.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan