Fume extractors

Clearing the Air: Clean Air's CFD Technology Revolutionises Fume Cupboard Design

Sep 05 2023

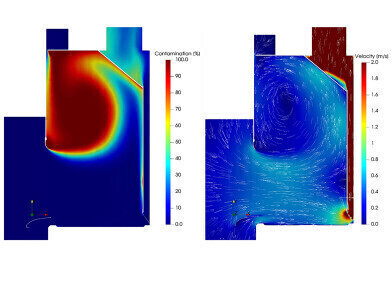

Clean Air is cutting carbon emissions and optimising containment through its pioneering use of Computational Fluid Dynamics (CFD) to design safer, greener fume cupboards. Our CFD capabilities are a game-changer for the industry, and demonstrate our commitment to sustainability, efficiency, and lab safety.

In the words of our Research & Development Manager, Dr Andrew Manning, "CFD isn't just a tool; it's a paradigm shift in how we engineer sustainable containment solutions. It empowers us to visualise the invisible and fine-tune designs with unprecedented precision. Clean Air's expertise in CFD has not only transformed our fume cupboard design process but will also contribute significantly to a greener future.”

Driving Efficiency: Sustainable Fume Cupboard Design

Imagine a car circumnavigating the equator 3.5 times. That's a conservative estimate of the amount of CO2e (~9 tonnes) an advanced CFD simulation saves on each new fume cupboard design. How did we achieve this astonishing feat? By harnessing the power of CFD, we've eliminated the need for physical prototypes and testing using SF6 gas. Our team meticulously analyses the intricacies of fluid behaviour, ensuring optimal performance and efficiency.

This doesn’t only improve design and containment, it translates into reduced emissions, cost savings, and quicker time-to-market, all while championing environmental stewardship.

Beyond Green: Combatting SF6 Emissions

Clean Air's dedication to environmental sustainability extends beyond design efficiency. We are committed to reducing our reliance on sulphur hexafluoride (SF6), notorious for its impact on the environment. This potent greenhouse gas has a staggering Global Warming Potential (GWP) of 22,800. It has traditionally been the standard gas for measuring fume purging effectiveness in fume cupboard design versions.

Through precise CFD simulations, Clean Air’s engineers have optimised containment systems, enabling us to eliminate SF6 usage in fume cupboard design without compromising safety. This proactive approach not only aligns with global emission reduction goals but also establishes Clean Air as a pioneer in environmentally conscious engineering practices.

Designing Safety: The Containment Conundrum

Lab safety is non-negotiable, and Clean Air goes the extra mile to ensure that each fume cupboard design delivers the highest level of protection. By leveraging CFD to analyse fluid behaviour and simulate complex scenarios, we can identify vulnerabilities and mitigate potential risks before they manifest.

This evidence-based approach ensures that our results are robust, reliable, and reproducible and our designs deliver excellent containment, even in the most demanding environments. The result? Cutting-edge solutions that prioritise safety.

A Holistic Transformation

As we look ahead, the whole Clean Air team is excited to push boundaries, foster creativity and facilitate positive change.

Meet us on Stand B66 at Lab Innovations 2023 for more information on Clean Air's CFD innovations and how we will use this remarkable technology to shape sustainable, safer, and greener laboratories in the future.

For more about our CFD innovation; read Dr Manning’s blog; or contact our friendly team.

Digital Edition

ILM 50.3 April 2025

May 2025

Chromatography Articles - Optimising two-step purification: Key considerations for sample pump setups Mass Spectrometry & Spectroscopy Articles - Detecting pharmaceuticals and their transf...

View all digital editions

Events

Making Pharmaceuticals Exhibition & Conference

Apr 29 2025 Coventry, UK

Apr 30 2025 Peshawar, Pakistan

May 11 2025 Vienna, Austria

May 13 2025 Oklahoma City, OK, USA

May 14 2025 London, UK