Chromatography

Waters design a simple and flexible sample delivery system.

Dec 01 2010

Goal

To design a simple and flexible sample delivery system with low dispersion that can be utilized for both UPLC® and HPLC. Key performance characteristics such as minimized carryover, precision, and accuracy without sample discrimination must be preserved across a broad range of injection volumes.

Background

There are two common injector design strategies used in autosamplers, the fixed-loop and the needle-in-flow-path designs. Each approach has its benefits and/or drawbacks in terms of performance, throughput, and usability. The alternative designs allow an analyst to choose the solution that is best for their chromatographic goals. Fixed-loop designs are preferred for applications that require the lowest extra-column band spread for high resolution separations. They also tend to have the fastest cycle times since the needle is off-line during analysis for cleaning and next injection preparation. However, these autosamplers often require some method development for optimal performance. Comparatively, autosamplers that utilize a needle-in-flow-path design provide the greatest flexibility and ease of use. This style of sample delivery typically offers the widest injection volume range without the need for multiple configuration changes. Most importantly, it requires very little method development for optimal performance.

The Solution

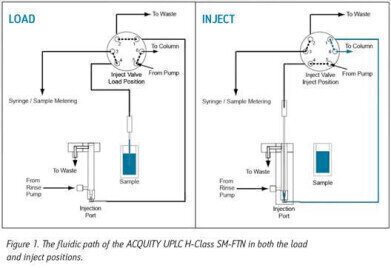

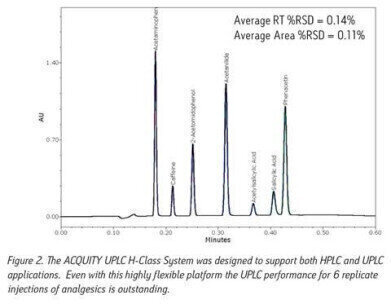

The ACQUITY UPLC® H-Class System with its flow-through-needle design sample manager (SM-FTN) addresses two design challenges for reliable UPLC performance: robust sealing of the needle at high pressures, and minimizing the extra-column band spread for narrow UPLC peaks. These challenges have been addressed with innovative design features and are highlighted by taking a detailed look at the injection sequence (Figure 1). Once an injection is initiated, the inject valve diverts flow from the needle so it can collect sample from the vial. The sampling mechanism is an RΘZ configuration (versus XYZ) in which the needle only moves in a diagonal direction and the sample tray rotates to position the vial under the needle’s path. The needle is lowered into the vial to withdraw the exact volume requested and returns to the injection port. The needle lowers and pushes against the internal sealing surface of the port. A force transducer measures the sealing force and only applies the pressure needed to seal to 15,000 psi, ensuring that no leaks will occur and the lifetime of the sealing surface is maximized. Finally, the injection valve turns and the sample is pushed down the injection port, through the injection valve, and out to the column. The injection port is located as close as possible to the inject valve to minimize dispersion of the sample as it travels to the chromatographic column. After the injection is made, the needle is washed for a specified amount of time to minimize sample carryover. With the flow-through needle design, the wide injection volume range required to run both HPLC and UPLC applications is achieved. The system’s flexible design is still ideally suited for low dispersion UPLC separations with typical band spread of 8 to 9 μL (Figure 2).

Summary

The ACQUITY UPLC H-Class System was designed to expand the benefits of UPLC Technology into laboratories focusing on method development/transfer, QA/QC, and routine analysis. The SM-FTN autosampler fits into the workflow of these laboratories by offering a simple, flexible design while maintaining the performance requirements of low-dispersion UPLC separations.

For the full Technology Brief go to ACQUITY UPLC H-Class Sample Delivery

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan