Chromatography

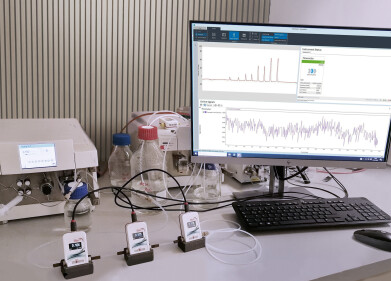

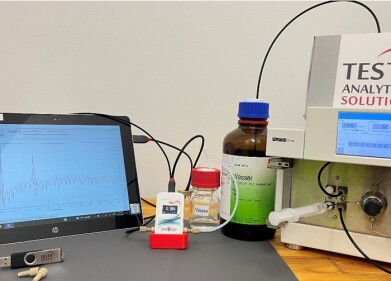

First UPLC-Based Analyser for the Process Development Laboratory

May 24 2011

The Waters PATROL UPLC Laboratory Analyser is designed to meet the needs of process development laboratories for the fast-turnaround of quality analytical data.

Built on proven Waters UltraPerformance LC® (UPLC®) technology, this new system solution provides scientists with mission-critical analytical data to guide decision-making at the earliest stages of manufacturing process development.

With the introduction of the Waters PATROL UPLC Laboratory Analyser, scientists can now deploy Real-TIME LC™ in an automated manner for process-related data acquisition and decision making on two new fronts: on the manufacturing floor with the PATROL UPLC Process Analyser and, now, in the process development laboratory

“The path to better process management and lower cost manufacturing passes through the process development laboratory,” said Craig Dobbs, Program Manager, Process Analytics, Waters Division. “UPLC technology has proven itself over the past eight years in discovery, research, and development labs with its superior ability to detect and quantify components of complex reaction mixtures and fully characterise a candidate molecule by LC, LC/MS, and LC/MS/MS. For the first time the process development lab, enabled by the PATROL UPLC Laboratory Analyser can leverage this historical QbD characterisation data for direct design space development, guiding decisions to optimise the chemical synthesis process by monitoring CQAs through scale-up and pilot production to full-scale manufacturing.”

Designed and engineered to perform lab to pilot-scale online and atline reaction monitoring in the process development laboratory, the PATROL UPLC Laboratory Analyser System provides accurate, reproducible, and precise chemical reaction mapping across the entire time course of the process. With Real-TIME LC™ and LC/MS information, scientists are able to fully characterise reaction kinetics and determine which process produces the desired endpoint.

A hallmark of the system is its dilution accuracy, linearity, and range. The technology behind this performance is the instrument’s new Process Sample Manager (PSM) which automatically extracts an online sample from a reactor or slipstream, performs sample prep, and sample injection – a process that once required the time and full attention of an analytical technician. In addition to online samples, the PSM can also accept and store up to 32 barcode labelled vials, which can be a combination of different standards, controls, and at-line samples.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan