-

Van Deemter curves measured using different carrier gases (Shimadzu Corporation, Kyoto, Japan)

Van Deemter curves measured using different carrier gases (Shimadzu Corporation, Kyoto, Japan) -

Schematic of Nexis GC 2030 with hydrogen sensor

Schematic of Nexis GC 2030 with hydrogen sensor -

Automated gas saver and gas selector fuctionalities of Nexis GC 2030

Automated gas saver and gas selector fuctionalities of Nexis GC 2030 -

Schematic of Nexis GC 2030 with gas selector

Schematic of Nexis GC 2030 with gas selector -

Smart automatic start/stop functionalities of Nexis GC 2030

Smart automatic start/stop functionalities of Nexis GC 2030

Chromatography

Short on helium? Consider the carrier-gas alternatives

Feb 08 2023

The advantages of using hydrogen and nitrogen in gas chromatographic measurement

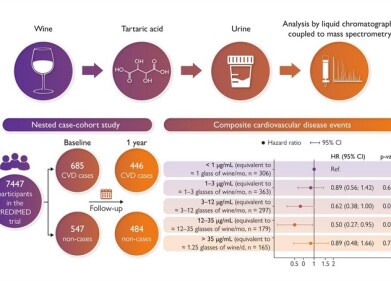

Helium is a preferred carrier gas in gas chromatography because of its high inertness and abilities supporting chromatographic separation. Demand for helium has been increasing, but limited availability and current events have exacerbated a pre-existing helium shortage. Prices therefore continue to rise, forcing users to look for alternatives. Nitrogen and hydrogen offer great potential to GC users. Both have drawbacks, but together with flexible gas-type selection and reduction of consumption they offer the key to success.

In gas chromatography (GC), the carrier gas transports the sample from the injection system via the separation column to the detector. Helium is a preferred carrier gas due to its high inertness and good separation abilities. However, it is a limited natural resource, and demand has been rapidly increasing for use in ever more applications in the medical, scientific, and industrial fields. Current circumstances have restricted supplies and lengthened delivery times, resulting in a helium shortage. This has led to rising prices, and some labs have been having a hard time getting any helium at all.

What are the choices?

Historically, inert gases were commonly used for gas chromatographic systems as they are easy and safe to handle. Helium and nitrogen were the most popular choices available among the inert gases.

Hydrogen is the best alternative to helium with respect to gas chromatographic separation. It is a highly efficient carrier gas that maintains its separation efficiency across a wide linear velocity range. In addition, hydrogen has no supply limitations, as it can be mass-produced by gas generators.

That said, hydrogen is reactive and bears an explosion risk if the concentration rises to 4% in the air. So strict precautions for safe operations with the gas must be taken. In addition, hydrogen is not always an appropriate carrier gas, especially when used with certain detection systems, or advanced techniques used in gas chromatography.

Using hydrogen safely in GC

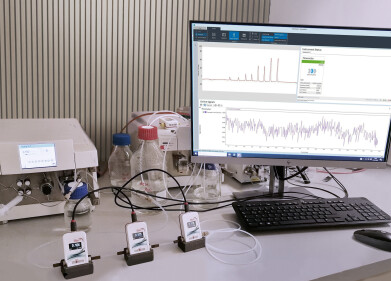

The Shimadzu Nexis GC-2030 offers a three-pillar safety concept that supports the safe use of hydrogen as a carrier gas. A preventative, automatic leak-check function helps the operator to check for possible leakages after any kind of column maintenance.

To cope with the risks resulting from less severe leakages or breakages of the capillary column during operation, independent hydrogen sensors for checking the air inside the column oven are available. The basic sensor shuts off the carrier gas control once a level of 1% of hydrogen in air is reached (Figure 2).

Another suitable alternative for helium is nitrogen as carrier gas. Different to hydrogen nitrogen is an inert gas and does not require any additional safety precautions. The use of nitrogen as carrier gas is restricted by the chromatographic separation abilities. In the Van Deemter curves (Figure 1) can be seen that the optimum separation with nitrogen can be only achieved within the lowest linear velocity range of the carrier gases resulting in longer running times per analysis. However for applications without challenging separation, it can be a suitable alternative to helium.

Cutting costs by reducing helium consumption

Helium is expensive, so users interested in efficient gas usage and instrument utilisation need to consider both the active analysis times of a gas chromatograph and instrument standby times. To help reduce costs, the Nexis GC-2030 supports an automated gas selector for convenient gas switching between analyses and for standby times, facilitating the use of different gas types on the same instrument. This can be used for carrier and/or make-up gas selection and offers the choice between two gases that are simultaneously connected to the selector inlets (Figure 3).

Safety. Value for money. Flexibility.

To reduce over-reliance on increasingly unavailable and progressively expensive helium, the Shimadzu Nexis GC-2030 supports cost-efficient gas chromatographic measurements with nitrogen and hydrogen as lower-cost carrier gas alternatives to helium. Nitrogen can be a substitute for helium as carrier gas if longer chromatogram times are acceptable. Hydrogen allows a significant reduction of chromatographic runtimes, increasing sample throughput without compromising reliability of the results. And the Nexis GC-2030 reduces the total amount of whatever carrier gas is used.

In addition, an automatic gas selector enables convenient gas switching between different analyses and during standby periods. Smart automatic features help to optimise the GC’s daily working time and gas consumption, further reducing running costs.

Finally, the Shimadzu Nexis GC-2030 ensures lab safety for users and their equipment and offers the most economical safety option for using hydrogen as a carrier gas. The Nexis GC-2030 comes equipped with automatic leak-check functionality and hydrogen sensor solutions with automatic safety features to ensure a safe working place.

Shimadzu understands the concerns and bottom-line challenges of gas chromatography users. The Nexis GC-2030 is designed to help labs reduce costs by reducing gas-carrier amounts and by safely and flexibly utilising the full potential of lower-cost alternates to helium.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan