-

German design, German manufacture

German design, German manufacture -

Simple outside, quality inside

Simple outside, quality inside

Chromatography

The Humble Gas Generator

May 10 2016

Almost every laboratory has a gas generator. Hidden amongst the flashy, expensive spectroscopy and chromatography instruments these humble workhorses are what keeps the critical equipment running. Any problem with the gas generator is a problem for the instrument it is supporting. Unnecessary downtime due to a faulty gas generator can cost thousands in a high throughput laboratory.

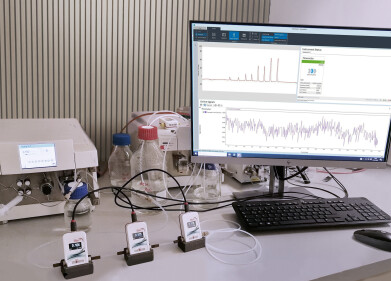

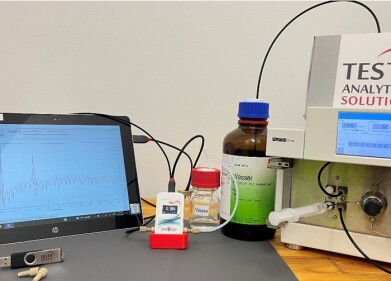

A simple box on the outside, not all gas generators are the same on the inside. For the past 25 years cmc Instruments GmbH have been designing, engineering and manufacturing a full suite of gas generators. They are deliberately ‘over engineered’ and use the best quality components. The ‘over engineering’ means the components are under no stress, these gas generators carry on happily for years with only minimal service requirements.

Excellent, low lifetime costs result in less downtime, better economy and large financial savings over cheaper equipment. That is probably why cmc Instruments are a market leader in Germany - a country still synonymous with quality and reliability.

Membrane type nitrogen generators are widely used in LC-MS applications to provide 99.5% nitrogen. Where cmc Instruments differ from the other manufacturers is that no service contract is necessary, there is no in-built compressor to create vibration, overheating and deliver moisture to the membrane. Compressors will need replacing eventually but the nitrogen membrane will also become irreversibly damaged. The result - increased downtime, higher costs and replacement parts.

Nitrogen generator systems from cmc Instruments do not run this risk. The quality runs right through the system. The membrane is of higher quality and lower ratio than the norm in these instruments, ensuring a longer lifetime. Four filters further ensure that only clean, dry air is presented to the membrane. Annual maintenance involves a filter change and can be performed by the user in fifteen minutes.

PSA type nitrogen generators provide UHP nitrogen (>99.9995% purity) for carrier gas applications in GC and other areas where the purest nitrogen is required. All models can be customised with the features you want, you don’t have to pay for features you don’t want.

Hydrogen generators are used in carrier gas, flame gas and FID gas applications in a variety of GC applications. Unlike other types of gas generator hydrogen generators involve flowing water, electricity and an explosive gas. There is plenty that can go wrong. Safety and reliability are key in deciding the best choice of hydrogen generator.

Zero air generators are widely available, apparently quite simple instruments, but they are not all the same. The cmc Instruments range of zero air generators use comparatively low energy and have excellent heat exchange characteristics. The catalytic element does not need regular changing. The result – lower downtimes, lower running costs, lower consumables costs, no service contract necessary.

Purge gas generators and TOC gas generators complete the full suite.

The belief at cmc Instruments is that it is not how much you pay on day one that matters. It is the years of service, the cost of ownership and lowest possible downtime that are most important. Customers tend to agree. Currently cmc are seeking to expand international distribution and are keen to welcome quality conscious distributors from all areas.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan