Chromatography

Advantages of Combining Flow and Pressure Control

May 16 2017

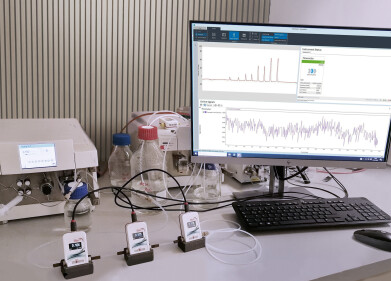

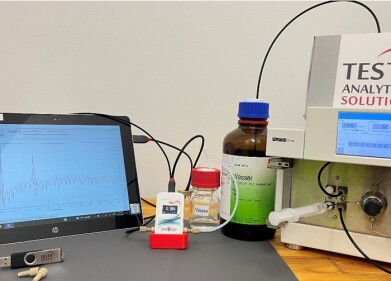

In a number of applications, both pressure and flow control play an important role in achieving system performance. One typical example of such an application is split/splitless injectors in gas chromatography (GC).

In gas chromatography, the choice between maintaining constant flow and maintaining constant pressure depends on a multitude of factors such as analytic type, sampling method and detector type. When maintaining pressure constant, flow rate can decline with increasing column temperature. This can lead to incompatibility issues with certain detector types, e.g. mass spectrometers and thermal conductivity detectors. When maintaining flow constant, higher pressures may need to be used, and this may fall out of the range of certain instruments.

Keeping the many advantages and disadvantages of flow and pressure control in mind, one possible solution is to combine both. Axetris mass flow meters and controllers can be easily combined with pressure sensors to build compact and fast-reacting flow+pressure controllers. Due to the quick reaction time achievable with the Axetris MEMS-based thermal mass flow technology, they lend themselves to easy integration as the controlling element in a pressure control loop. Axetris application experts help OEMs worldwide optimally combine flow and pressure control to achieve maximum performance.

Digital Edition

Lab Asia 31.6 Dec 2024

December 2024

Chromatography Articles - Sustainable chromatography: Embracing software for greener methods Mass Spectrometry & Spectroscopy Articles - Solving industry challenges for phosphorus containi...

View all digital editions

Events

Jan 22 2025 Tokyo, Japan

Jan 22 2025 Birmingham, UK

Jan 25 2025 San Diego, CA, USA

Jan 27 2025 Dubai, UAE

Jan 29 2025 Tokyo, Japan