Laboratory Products

Did We Sterilise?

Feb 08 2016

Author: Tony Collins on behalf of Priorclave Ltd

Whatever the industry, whether it is food and beverage, dairy, pharmaceutical, educational, research or health care, the reasoning behind that laboratory autoclave purchase is to ensure instruments and lab accessories that we want to reuse are safe and contaminant free; also waste to be discarded is sterile. The overall objective is that of destroying any micro-organisms; improperly autoclaved items could result in contamination, lost time and wasted money and much worse in extreme circumstances.

With such importance placed on the role of the autoclave how do we monitor the effectiveness of the steam sterilisation process?

Perfecting Sterilisation

The chamber of the autoclave is a sealed pressure vessel where steam at temperatures up to 140ºC and a pressure of 2.4bar can be generated.

An effective autoclave or steriliser must contain dry saturated steam. In order to achieve this, air must be removed from both the load and the chamber which can be accomplished in a number of ways. Air removal from high mass low surface area items (i.e. comprising mainly solid areas that contain little or no air pockets such as bottled media) will need little air removal and this can be facilitated by automatic air purging. Here air is allowed to leave the chamber through a vent as steam enters the chamber either from an integral source (upward displacement) or an external supply (downward displacement) with the vent only closing when all of the air is removed from the chamber.

This method can be further advanced by ‘Freesteaming’ when the vent is allowed to stay open for a set length of time once the autoclave is above 100ºC. The turbulent steam then passes through the vent forcing any trapped air out of the autoclave. In some systems this can also be pulsed by repeatedly allowing pressure to build and then releasing it. Freesteaming of liquid loads is useful in a different way as it effectively holds the autoclave chamber at 100ºC so that the liquid load temperature can catch up with it. Pulsed Steaming is not suitable for liquid loads however.

For more stubborn loads that contain a number of air pockets such as wrapped instruments or fabrics, a more effective method of air removal such as a vacuum system is essential.

There is no simple formula for how long a certain item needs to be autoclaved to achieve sterility. Consideration must be given to the type of primary container (the beaker, flask or packet), the volume of liquid, amount of solid material and any secondary container such as a tray containing the primary container.

Cycle times will vary with the composition of the load therefore it is important to determine the appropriate time requirement. The contents of the autoclave will heat more slowly than the autoclave itself so when you reach the set sterilising temperature what temperature have the contents reached? You could assume that a time of 30 minutes is a sufficient safety margin and most of the time you would probably be right, but what if you are not?

Validating Sterilisation

To ensure fulfilment of a sterilisation process calls for validation and performance qualification for each and every different load.

Sterilisation process validation is a procedure for obtaining, recording and interpreting the results required to establish that the process yields reliable, repeatable load sterilisation complying with predetermined specifications for sterility.

It must be remembered that the load is part of the validation process; the test load must be typical of loads actually processed as the results cannot necessarily be taken for granted if the load varies. Should the user make significant changes to the load at any point in the future, then revalidation may be necessary.

Validation and routine control of sterilisation by moist heat, i.e. steam sterilisers, need only be performed at initial installation provided that the autoclave is regularly calibrated and after certain repairs. For most laboratory applications validation testing is normally sufficient.

Performance Testing - key to understanding what is actually happening to the load.

Performance Testing is usually achieved using a calibrated, multi-channel, data logger so that considerable numbers of points in the load, together with salient points on the autoclave, can be logged throughout a hold time. Once qualification of the empty chamber has been accepted, load testing should be performed. Probes are placed inside typical loads and the heat transfer time is determined, producing a temperature profile during the sterilisation cycle.

Simultaneous monitoring of the chamber pressure is also useful in checking the efficiency of the air removal/replacement system.

Analysis of these results may point to problems in the setup of the autoclave or in the way the load is contained. Significant differences can be seen, for instance, between glass and plastic bottles or plastic and metal discard containers, or between single and double bagged discard loads.

A good calibration laboratory will consider and discuss these factors with the customer prior to their engineer arriving. However, once the performance qualification is done, calibration alone thereafter is often sufficient, at least if the load does not change.

During the load testing, biological indicators may also be placed in the load to determine if sterilisation is in fact taking place.

Temperature Monitoring: Temperature recorders, printers and built in loggers are available for autoclaves although these strictly speaking only give an indication that the autoclave itself has run correctly for the duration of the sterilising cycle. They are useful as a routine check to pick up cycle irregularities but they will not detect anomalies within the load itself during a normal cycle.

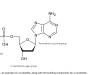

Biological and other indicators: On a day-to-day basis the effectiveness of sterilisation of any one particular run can be checked with the use of indicators placed within the load. These include autoclave tapes and indicator strips that change colour with temperature, more sophisticated strips that will only change colour when they experience the correct temperature and pressure for sterilisation and biological indicators that contain viable bacterial spores, which can be incubated after sterilisation to check for viability.

In most laboratory installations, commissioning and performance testing of loads to be sterilised are sufficient to meet requirements and should only be carried out by suitably qualified and experienced personnel.

Results Recognition

In order for the results to be recognised the methods used and the calibration of the equipment used should be regulated by a recognised body. In the UK this function is carried out by UKAS (United Kingdom Accreditation Service). It is the only organisation recognised by the UK government to assess calibration laboratories against international criteria. (Visit: www.ukas.org for more details).

Commissioning and performance qualification of an autoclave and subsequent validation of the sterilising protocols is a costly and time consuming process, both in terms of the actual procedures involved and also in analysis and review of the resulting documentation. However the costs should be reviewed in light of human safety rather than economics, on the plus side a properly set up and loaded autoclave will be faster and more energy efficient than one where large margins are added to the variables to achieve sterilisation.

Where the performance of the steriliser is critically important a fully documented and recorded purchasing and approval process is required.

Performance qualification (PQ) is a series of tests that establishes that the installed and properly operating autoclave will process efficiently and effectively the users desired chamber loads to the specified sterility assurance level (SAL).

The primary goal for the commonly employed overkill validation is that the user needs to complete three consecutive successful half cycles in order to qualify their proposed full-cycle exposure for routine processing of sterilisation loads. If, for example, there was no BI growth for the three test cycles at ten minutes exposure at 121°C, then a 20 minute exposure at the same temperature would be adequate for routine daily processing.

The results of all commissioning tests and performance qualification tests should be fully recorded, reviewed, accepted and archived by the relevant personnel in the organisation that uses the autoclave. These results may be recorded on suitable worksheets and certificates may be issued by third-party organisations that perform such tests.

Safety Assured

Validation and performance qualifications are an approval status that the autoclave is fit to use. Should the temperature in items being sterilised reach the set temperature for the required time, not all spores will be destroyed. Validation is therefore required to ensure that the autoclave is operating correctly and that complete sterilisation is being achieved. Also regular calibration will ensure that the initial expenditure on performance testing retains its value.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 22 2024 Marrakech, Morroco

Making Pharmaceuticals Exhibition & Conference

Apr 23 2024 Coventry, UK

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Seoul, South Korea

Apr 24 2024 Jakarta, Indonesia

.jpg)